Why choose us?

1. Professional factory: We produce plastic granulator machine for more than 23 years. We are expert to know how to design the machine rationally.

2. Reasonable Price: We produce plastic granulator machine in large quantities. Cause large-scale operation, for the same category and same quality machine, our price is most competitive, 10%-20% lower than others.

3. High output: For the same category and same quality machine, the capacity of our machine is 20% higher than others.

4. Good quality: The lifetime of our machine is 30% longer than others.

5. Low power consumption: 10-20% lower than others.

6. Free installation & training: quickly solve after-sales problems within 24 hours.

How about this Plastic Granulator Machine?

Items | We | others |

Equipment applicable raw materials | PP, PE film, bag or bottles | PP, PE film, bag |

Max capacity | 400kg/h | 280kg/h |

Energy consumption | 450KW.h/T | about 550KW.h/T |

Screw material | 38CrMoAIA | 38CrMoAIA |

Screw size(Max) | Φ250 | Φ245 |

reducer | Hard gear reducer | Common reducer |

Heating ring | Electromagnetic + ceramic | quartz |

Cooling tank material | stainless steel (304) | 45# steel |

Motor | Siemens, Huatiao | Cheap motor |

Exported countries | More than 20 countries including America, Japan, Vietnam, Saudi Arabia, Egypt, Jordan, Russia, Italy, Brazil, Argentina, etc | Mainly for domestic market |

Technical strength | We not only produce Plastic Recycling Machine for Making Plastic Pellets, but also use Pellets to produce plastic straps. Accumolate more than 23 years experience, customer can totally copy our experiences on strap marketing, producing, to success fast | Only produce strap machine, lack of strap marketing and producing experiences |

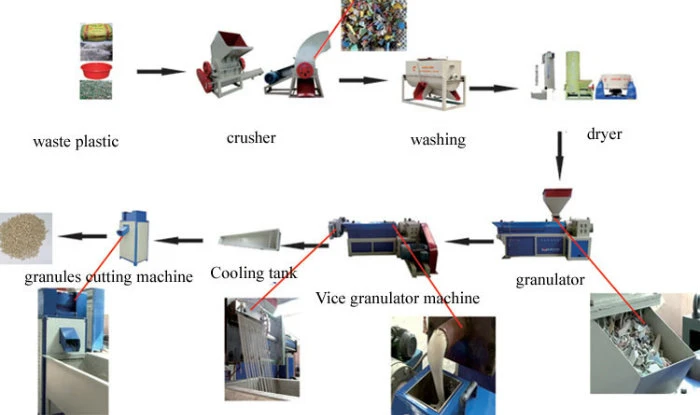

Product Show

| NO. | Name | Function | Qty(set) |

| 1 | Feeder System | Transfer the clean raw material into extruder machine | 1 |

| 2 | Master Granulator | Plasticizing the raw material and filter dirty | 1 |

| 3 | vice Granulator | Plasticizing the raw materia | 1 |

| 4 | Cooling Tank | Cooling of the material | 1 |

| 5 | Pelletizer | Cutting the granules | 1 |

| 6 | Electric control cabinet | Control the whole granulator line running | 1 |

After-sales service

1.We provide one-year warranty guarantee for all the machines. We supply long term spare parts for every customer and 24 hours technical suport by email, calling and door to door service;

2.We run machines in our factory before delivery. Clients check machines running in our factory, and when machines arrive in Client's factory, we will send our engineer to run machines in client's factory too.

3. we provide service manual and maintenance instruction of main electric appliance,usage manual of equipment.

4.We also supply installation drawing of water, electricity, gas of equipment.

1. Study plastic recycling process since 1995;

2.Produce the plastic granulate and the plastic recycling machinery at the same time.

What's the deal process?

Test equipment to factory-- confirm equipment performance index-- pay deposit--equipment production complete performance confirmation--to factory site operation training, to delivery-- installation and commissioning, technical guidance

FAQ

1.How long is the delivery time of the equipment?

In the case of standard configuration, the equipment is delivered within 40 working days.

2,What is the charging standard for equipment installation and commissioning?

For the first time installation and commissioning, our company only collects the travel expenses and visa fees of the security personnel. The buyer needs to be responsible for the accommodation and accommodation of the engineer.

3.Is there a charge for the on-site operation training?

No

4.Can your equipment be upgraded in the future?

of course can

5.How to solve your equipment if there is a problem? How long can it be solved?

The equipment technology is mature. Under normal circumstances, as long as it is operated properly, there will be no major problems. If the customer is unable to solve the problem, based on the timeliness, first communicate with our engineers through the network. If the communication still cannot be solved, we will send the work to the customer site within 48 hours

6.If I buy your equipment, can I buy accessories for a long time?

Our wearing parts are stocked to ensure that the production is not delayed.

7.You will not be a foreign trade company without a production factory.

We are a production-oriented factory, and we have the right to export at the same time, we can export ourselves. Self-produced

8.What are the ways we pay?

Our payment methods are T/T and letter of credit.

If you are involved in this industry for the first time, please send me an enquiry, we provide an investment analysis for your reference.

If you want to know more information of our Plastic Recycling Machine for Making Plastic Pellets,please contact me directly.

Best Regards.