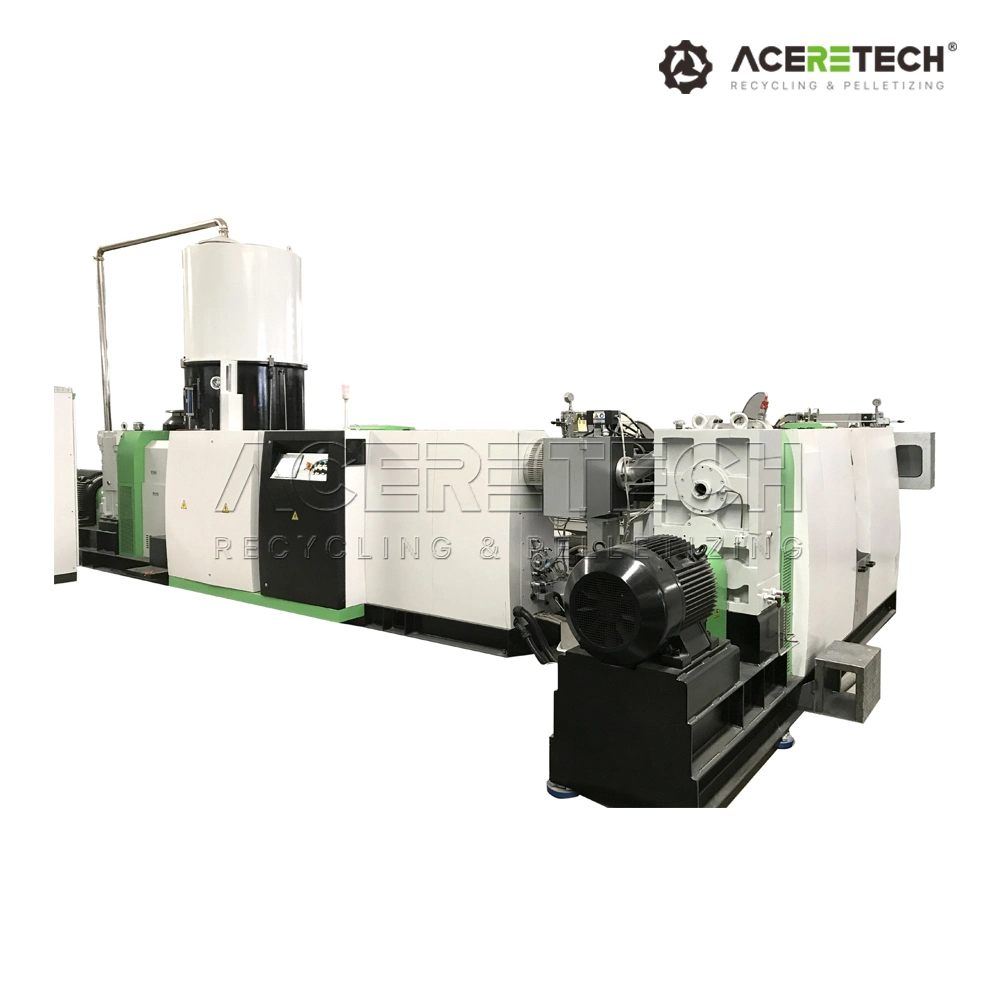

Hot Sale Recycled Plastic Pellets Recycling Machine Plastic Granulator Plastic Pelletizer

The ACS-Series compacting and pelletizing system combines function of crushing, compacting, plasticization and pelletizing to one step, applied in the plastics recycling and pelletizing process. ACS-Series is a reliable and efficiency solution for plastics films, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

Final productions produced by ACS-Series are in the form of pellets/ granules, can directly put into the production line for film blowing, pipe extrusion and plastics injection, etc.

Specifications:

Working steps of ACS-Series compacting and pelletizing system

1. Feeding: as standard design, plastic scraps such as film, filament, raffias conveyed into the compacting room through belt conveyor; to handle rolls' scraps, roll hauling off device is an optional feeding method. Motor drives of conveyor belt and hauling device cooperate with ABB inverter. Feeding speed of conveyor belt or roll hauling off is fully automatic based on how full the compactor's room is. Metal detector can be combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal is found in feeding section.

2. Crushing and compacting: the rotatory blades of compactor will cut up incoming scraps. Frictional heating which caused by high speed rotatory blades will heat and let scraps shrinking just below their agglomerating point. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder.

3. Plasticization and degassing: A specialized single screw extruder applied to gently melt the pre-compacted material. The plastic scraps will be well melted, plasticized in a 32 to 34D processing section. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

4. Melt filtration: a regular single-plate/ piston double-station screen changer or non-stop double-plate/ piston four-station can be installed on head of extruder to present significant filtration performance. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules.

5. Pelletizing: die-face water ring pelletizing system set as the standard granulating method in ACS system. Self-adjusting pelletizing head for the best granulate quality and long uptime thanks to consistently correct blades pressure. RPM of rotatory blades is automatic based on melt extruding pressure. Advanced dewatering vibration sieve combining with horizontal-type centrifugal dewatering present high performance dried pellets.

Main technical parameter:

Advantages of ACS500/100 compacting and pelletizing system

1. Size reduction,pre-heating and pelletizing,3 in 1 integrated system,less cost.

2. More effective and stable system for plastics of low bulk density.

3. Higher output and lower energy consumption.

4. Lower investment for a higher performance machine.

5. Standard production and management in the workshop.

The ACS-Series compacting and pelletizing system combines function of crushing, compacting, plasticization and pelletizing to one step, applied in the plastics recycling and pelletizing process. ACS-Series is a reliable and efficiency solution for plastics films, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

Final productions produced by ACS-Series are in the form of pellets/ granules, can directly put into the production line for film blowing, pipe extrusion and plastics injection, etc.

Specifications:

| Model Name | ACS-Series |

| Recycling Material | HDPE, LDPE, LLDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, EPS |

| Final Product Shape | Pellets/ Granules |

| System Composition | Belt conveyor, cutting compactor, single screw extruder, pelletizing device, water cooling unit, dewatering section, conveying blower and production silo |

| Output Range | 300kg/h-380kg/h |

| Feeding Device | Belt conveyor (standard), Rolls hauling off device (Optional) |

| Compactor Volume | 300-1400 Liters |

| Screw Diameter | 80-180mm (standard) |

| Screw material | 38CrMoAlA nitride steel( SACM-645), bimetallic ( Optional) |

| Screw L/D | 31/1, 32/1, 34/1, 36/1 (depending on features of recycles) |

| Barrel's Heating | Ceramic heater or Casting Aluminum heater |

| Barrel's Cooling | Air cooling through fan blowers |

| Vacuum Degassing | Double vented degassing (Standard) |

| Pelletizing Type | Water ring die-face hot pelletizing |

| Voltage Standard | Depending on project's location |

| Optional Devices | Metal detector, rolls hauling off device, micro feeder for masterbatch, additives, chiller, etc. |

| Delivery Time | 60 days after order takes effect. |

| Warranty | 13 months since date of bill of lading |

| Technical Service | Project design, suggestion on factory construction, installation and commissioning |

Working steps of ACS-Series compacting and pelletizing system

1. Feeding: as standard design, plastic scraps such as film, filament, raffias conveyed into the compacting room through belt conveyor; to handle rolls' scraps, roll hauling off device is an optional feeding method. Motor drives of conveyor belt and hauling device cooperate with ABB inverter. Feeding speed of conveyor belt or roll hauling off is fully automatic based on how full the compactor's room is. Metal detector can be combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal is found in feeding section.

2. Crushing and compacting: the rotatory blades of compactor will cut up incoming scraps. Frictional heating which caused by high speed rotatory blades will heat and let scraps shrinking just below their agglomerating point. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder.

3. Plasticization and degassing: A specialized single screw extruder applied to gently melt the pre-compacted material. The plastic scraps will be well melted, plasticized in a 32 to 34D processing section. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

4. Melt filtration: a regular single-plate/ piston double-station screen changer or non-stop double-plate/ piston four-station can be installed on head of extruder to present significant filtration performance. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules.

5. Pelletizing: die-face water ring pelletizing system set as the standard granulating method in ACS system. Self-adjusting pelletizing head for the best granulate quality and long uptime thanks to consistently correct blades pressure. RPM of rotatory blades is automatic based on melt extruding pressure. Advanced dewatering vibration sieve combining with horizontal-type centrifugal dewatering present high performance dried pellets.

Main technical parameter:

| Machinery size | Data of compactor | Data of single screw extruder | Throughput rate(Kg/hr) | |||

| Efficiency volume(Liter) | Motor power(Kw) | Diameter of screw(mm) | L/D | Motor power(Kw) | ||

| ACS-H300/80 | 300 | 37 | 80 | 36 | 55 | 160-220 |

| ACS-H500/100 | 500 | 55 | 100 | 36 | 110 | 300-380 |

| ACS-H800/120 | 800 | 90 | 120 | 36 | 132 | 450-480 |

| ACS-H1000-140 | 1000 | 110 | 140 | 36 | 185 | 500-650 |

| ACS-H1200/160 | 1200 | 132 | 160 | 36 | 250 | 800-1000 |

| ACS-H1400/180 | 1400 | 160 | 180 | 36 | 315 | 1000-1200 |

Advantages of ACS500/100 compacting and pelletizing system

1. Size reduction,pre-heating and pelletizing,3 in 1 integrated system,less cost.

2. More effective and stable system for plastics of low bulk density.

3. Higher output and lower energy consumption.

4. Lower investment for a higher performance machine.

5. Standard production and management in the workshop.