Yatong Plastic PP PE Flakes Recycling Pelletizing Line / Granulating Machine / Recycling Line

Feeding type for PE film pelletizing machine:

1. hopper feeder (suitable for agglomerated material, hard scrap material)

2. with a separate agglomerator (suitable for film, bag etc)

3. compactor (suitable for bundled big size film bag)

4. reel feeder (suitable for film roller)

5. Side force feeder(suitable for film scraps, hard material scraps)

6. Vertical force feeder (suitable for film scrap and hard material scrap)

Pelletizing cutting type for PE film pelletizing machine :

1. water ring cutting

2. noodle string strand cutting

Extruder type for PE film pelletizing machine :

1. single stage

2. double stage

Welcome to send inquiry for more detailed machine specification and price, I will send you competitive offer very soon!

Feature and Function:

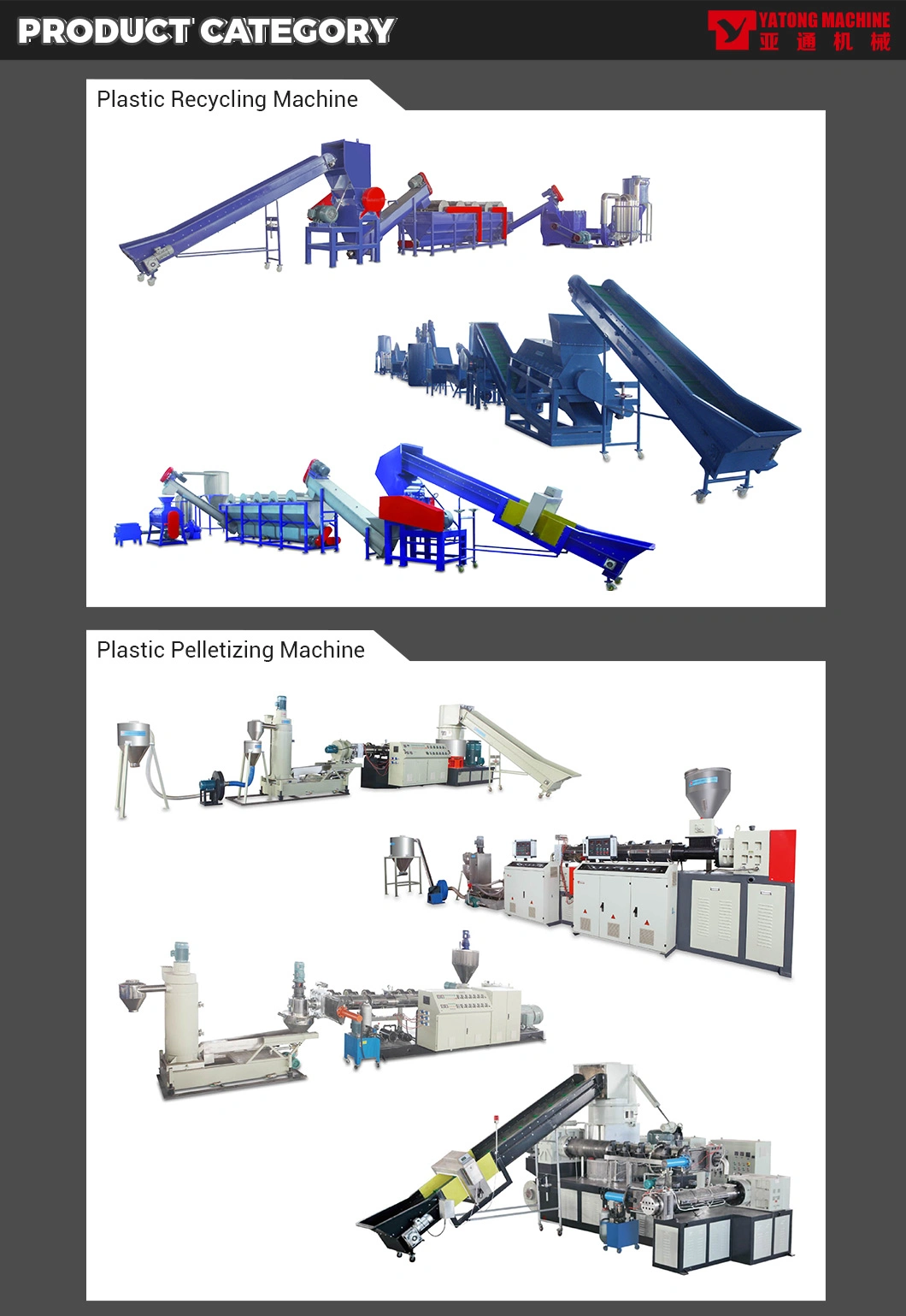

Water ring type pelletizing line,recycling PP PE film bags,make them into pellets.

Process flow:

Conveyor→ PP PE film force feeding→ Extruding system→ Die-head and High speed Net exchanging system→ water ring pelletizing machine → water tank → dewatering machine→ vibrating sieve→ Air Blower → Storage hopper

Detailed description

1. Conveyor:convey PP PE film or flakes into compactor.

2. PE film force feeder:force feeding PP PE film chips,rigid scraps into extruder.

3.Extruding system:plasticizing material and exhausting gas.

4.High speed Net exchanging system and Die-head:filter material impurity,to make production more stable.

5.water ring pelletizing machine:cutting pellets in water.

6.Water tank:cooling pellets.

7.Dewater machine:make pellets dry.

8.Vibration sieve:remove bad pellet and keep good pellet.

9.Air Blower:convey good pellets into silo.

10:Storage silo:keep pellet.

Single stage with force feeding

| Model | Screw Diameter | L/D | Output(KG/H) | Cutting Method |

| SJ75 | 75 | 25-33 | 100-200 | Die Face Cutting or Strand Cutting |

| SJ100 | 100 | 25-33 | 200-300 | |

| SJ120 | 120 | 25-33 | 300-500 | |

| SJ150 | 150 | 28-33 | 450-600 | |

| SJ160 | 160 | 28-33 | 550-700 | |

| SJ180 | 180 | 28-33 | 700-850 | |

| SJ200 | 200 | 28-33 | 800-1100 | |

| Note | The capacity is based on the raw material. The output for rigid flake and film flake are different, as well as the material. We offer solution based on the client`s actural requirements | |||

Double stage with force feeding

| Model | Screw Diameter | L/D | Main Motor | Output(KG/H) | Cutting Method |

| SJ120/120 | 120 | 20 | 37KW | 100-200 | Die Face Cutting or Strand Cutting |

| 120 | 10 | 15KW | |||

| SJ140/130 | 140 | 20 | 55KW | 150-250 | |

| 130 | 10 | 18.5KW | |||

| SJ150/140 | 150 | 20 | 75KW | 250-380 | |

| 140 | 10 | 22KW | |||

| SJ160/150 | 160 | 20 | 90KW | 400-500 | |

| 150 | 10 | 37KW | |||

| Note | The capacity is based on the raw material. The output for rigid flake and film flake are different, as well as the material. We offer solution based on the client`s actural requirements | ||||

Transportation and Packing

• For the loose cargo we will packing by wooden box

• For the full container loading we are packing the machine by film and some on pallet accordingly

• We can ship the goods by air or by sea

• We will send pictures of cargo loading to our client to check and keep recording

• We can send cargo to client's warehouse to loading

Our service:

• Pre-sale: we give our client the detailed technician offer, sign the sales contract etc.

• In-sales: we supply the details layout, installation instruction, and technician support for the clients.

• After sales: we arrange engineer to install the machine and train the workers for our client.

• We have 24 hours service line to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

• We always update the new technology to every customer.

In order to match your requirement and provide you a proper quotation, please advise:

• What material do you want to recycling? PE film? PP woven bag? HDPE PP bottle? or other plastic?

• What capacity(kg/h) do you want?

• What is the final size(mm) of flakes you want?

• Other special requirements about the waste plastic recycling pelletizing machine you want.

YATONG MACHINERY is a professional machine manufacturer dedicated to designing and developing the high technology plastic machine with more than 10 years' experience. Our developing concept is quality first, service foremost, and we are looking forward to cooperating with you for a bright future.