Machine Application:

The PET recycling washing line is suitable for washing, crushing , drying material of PET bottles.

Machine Features:

1. Capacity : 200kg/h, 300kg/h, 500kg/h, and 1000kg/h;

2. Different device selection base on your material;

3. Full automatic line or semi-automatic line;

4. Accept customized

5. Turn-key project , machine-installment-testing.

Machine Process Flow Introduction:

Bottle bales→Bale Opening→Trommel Filtering→Label Removing→Bottle Pre-washing→Manual Sorting→Wet Crushing→Floating Washing→Drying→Hot Flotation Washer→Drying→Continuous Friction→Continuous Floating Washing→Drying→Label&Dust remover→Flake Optical Sorting→

Packing→Clean Flakes

Machine Technical Characteristics:

1.Final recycled PET flake quality standard:

| Index | Parameter |

| PET flake size | 8~12 mm |

| Moisture | < 1.5 % |

| Viscose | < 20 ppm |

| PP/PE | < 20 ppm |

| Metal | < 20 ppm |

| Other color PET flake | < 30 ppm |

| Label | < 20 ppm |

| PVC | < 30 ppm |

| Total impurities | < 100 ppm |

| PH | neutral |

| Bulk density | 0.3g/cm3 |

2. Estimated Plant Parameter:

| Capacity(kg/h) | Installation Power(kw) | Required Area(m2) | Manpower |

| 500 | 220 | 600 | 8 |

| 1500 | 430 | 800 | 12 |

| 3000 | 650 | 1000 | 18 |

| 6000 | 1000 | 1400 | 30 |

| De-laber | Bottle bale opening |

| Belt conveyor | Put the material on the moving belt, which will convey the bottle into label remover |

| Trommel | Removing rock, stone, dust, loosen caps and small metals, especially, the iron will be removed by high speed |

| Bottle label separator | Removing labels from bottles |

| Manual Select working table | IF the label still in the bottle, worker can remove the label by hand |

| Crusher | Crush the material |

| Screw loader | Put the flakes into the Hot washer to clean |

| Floating washer | Cleaning flakes to remove chemicals and separating out rest labels and caps |

| Hot washer | Connected with steam boiler. Steam is supplied into washing tank to heat water and flakes. Hot water makes waste; label and glue loosen from bottles |

| Friction washer | After crushing material from enters the mouth, through the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect |

| Centrifugal dryer | Rejection the water from the flakes, moisture content is less than 2% |

| Pipe drying system | Hot air drying |

| PVC(label) separator | Used for the PET bottles, round and pressed bottles,effective more than 98%,save energy and labor,without water |

| Storage bunker | Storage materials |

Machine photos as a reference:

PET Bottle washing machine Packing details:

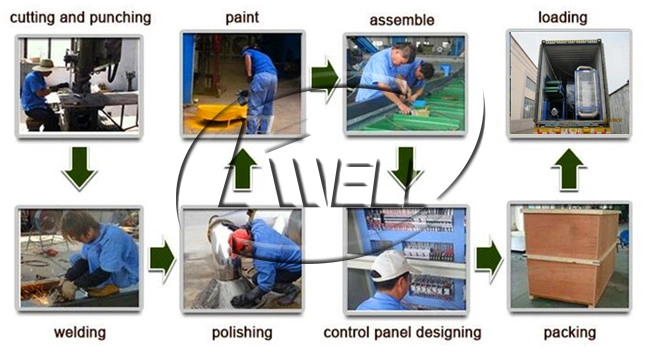

Working process:

About our service:

PET Bottle washing line Before-sale:

- Introduce products and applications detain

- Recommend suitable solution

- Provide with reference information

- Offer lab for test

- Provide with layout and engineering conditions

- Inform the project processing status

- Offer other documents

1. Provide with installation, commissioning and training

2. Register and record customer information

3. Offer spare parts

4. Provide with necessary technical support for new application

5. Visit customer regularly and correct information

Why choose us:

1. Lower investment cost for a high quality and durable machine;

2. Low energy consumption with high production output;

3. Overseas installation and training are available;

4. Machine warranty with spares in stocking and in-time delivery;

5. Fast machine delivery and installation: KWELL produces on an average of 10 sets of plastic machines per month and can deliver the machine faster than most manufacturers. The regular delivery time of an KWELL recycling machine is 30 days.

Please convenient yourselves by me !!

http://kwellgroup.en.made-in-china.com/