| Mode | Screw Diameter D(mm) | Screw Length(mm) | L/D | Screw Rater N(r/min) | Motor Power P(kw) | Torque T(N.m) | Torque Level T/N3 | Capacity Q(kg/h) | Weight(kg) | Dimension (m) |

| SHJ-20 | 22 | 150 | 32-44 | 600 | 5.5 | 43 | 7.5 | 0.5-10 | 1000 | 1.7*0.5*1.8 |

| TSE-30A | 31 | 32-48 | 500 | 11 | 105 | 5.9 | 5-30 | 1500 | 2.4*0.63*2 | |

| TSE-30B | 600 | 15 | 119 | 6.7 | 5-40 | |||||

| SHJ-35A | 35.6 | 32-48 | 600 | 15 | 119 | 4.4 | 20-60 | |||

| TSE-40A | 41 | 160 | 32-64 | 400 | 22 | 263 | 6.4 | 65-110 | 3000 | 2.9*0.65*2 |

| TSE-40B | 41 | 160 | 32-52 | 600 | 30 | 239 | 5.8 | 90-150 | ||

| SHJ-50A | 50.5 | 32-52 | 500 | 45 | 430 | 5.4 | 135-225 | |||

| TSE-52B | 51.5 | 210 | 32-64 | 600 | 55 | 438 | 5.5 | 225-250 | 3000 | 3.8*2*0.69 |

| TSE-52C | 51.5 | 210 | 32-64 | 600 | 75 | 597 | 7.5 | 200-300 | ||

| SHJ-65A | 62.4 | 240 | 32-52 | 400 | 75 | 895 | 6.3 | 180-250 | 4000 | 4.2*0.67*2.2 |

| 500 | 75 | 716 | 5.1 | 180-250 | ||||||

| TSE-65B | 62.4 | 240 | 32-64 | 600 | 90 | 716 | 5.1 | 200-300 | ||

| SHJ-75A | 71 | 290 | 32-56 | 400 | 90 | 1074 | 5.0 | 225-350 | 4000 | 4.8*0.78*2.3 |

| 500 | 110 | 1050 | 4.8 | 250-450 | ||||||

| TSE-75B | 71 | 290 | 32-64 | 600 | 132 | 1050 | 4.8 | 350-550 | ||

| TSE-75D | 71 | 290 | 32-64 | 60O | 220-250 | 1990 | 9.2 | 500-1000 | ||

| TSE-95A | 93 | 360 | 32-64 | 500 | 250 | 2387 | 5.0 | 600-1000 | 4000 | 6.2*0.87*2.4 |

| TSE-95B | 93 | 360 | 32-64 | 600 | 315 | 2506 | 5.3 | 800-1200 | ||

| TSE-135A | 133 | 32-64 | 500 | 750 | 7162 | 5.38 | 1500-2250 | 4000 |

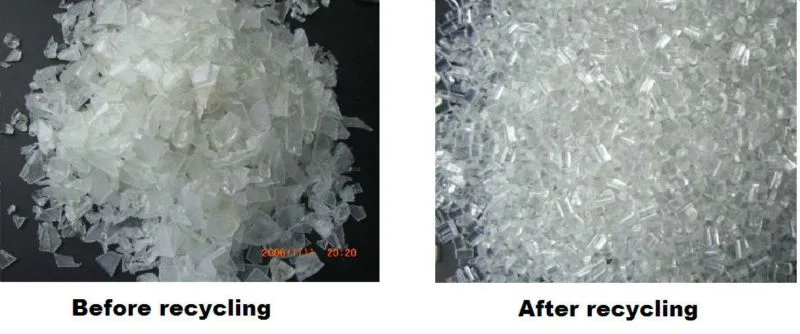

special for waste plastic recycling, and convert to PP PE PET PS ABS PA PVC etc granules.

Two stage machine has better performance in recycling pvc.

Functions:

Plastics filling and modification, general and fibre color masterbatch, blending modification (rubber and plastic blending, plastic alloy), functional masterbatch, glass fibre or carbon fibre reinforcement, various cable material, reactive extrusion, handling after venting and dewatering, special material, powder coating

Characteristics:1, Modular principle design for screw configuration and barrel setup makes combination and cleaning convenient , also easy to adapt to customers' requirements .

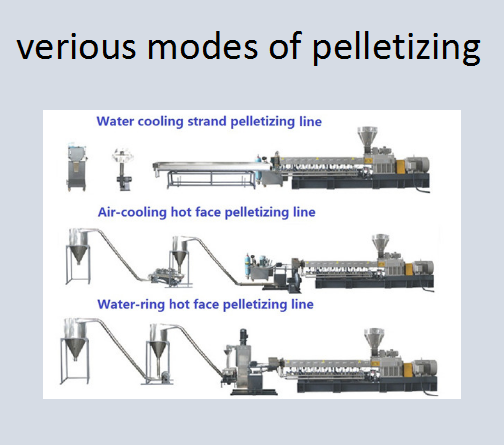

2, Different kinds of pelletizing modes can meet specific material properties: water-cooling strand pelletizing, air-cooling hot-cut pelletizing, water-ring pelletizing, under water pelletizing, etc.

3, Screw elements and kneading blocks are made of high tool steel , with high corrosion-resistant and high wear-resistant.

4, Barrels are made of high quality nitrided steel , corrosion proof and antifriction.

5, Vacuum system fulfills devolatilization to ensure the quality of polymer processing.

Parts1.The Gearbox

New-style project of parallel three-axises driving makes the convey axis,convey chain,decelerate and the torque assignment get together,which keeo it compact,and the key bearings are imported.

The select material of drive components is dainty. Including super intension alloy cementiteing steel,cementiting and quenching ,gear grinding technics ,strengthening of tooth face.So they can ensure high torque,high precision and low noise.

Soakage and coerce lubrication integrate smoothly.When the hydraulic circuit is over pressed, it alarms

2.Mixing and Feeding system

3.pelletizer Our company

Our company

Kairong group , headquartered in Nanjing, China, is a global manufacturing and trading company in the field of highperformance plastics and rubber processing equipment , extrusion solutions, masterbatch and compounding, etc. Its unit Nanjing Haisi Extrusion Company is a prefessional manufacturer of twin screw extruder, single screw extruder ,two stage extruder and its related auxiaries. We tailor solutions from raw materials, materials processing equipment, to injection for different customers. Each Kairong solution is designed , manufactured, and commissioned by experienced teams of professionals engineers and aftersales staffs.

when customers buy our machines, first we promise good quality, lead customers visit our factory to check machines, when machines are ready and tested, we deliver according to customers' requirements, after machines arrive desination, if any problem, we try our best to solve asp, and we will arrange our engineer to go abroad to teach and test if customer need.