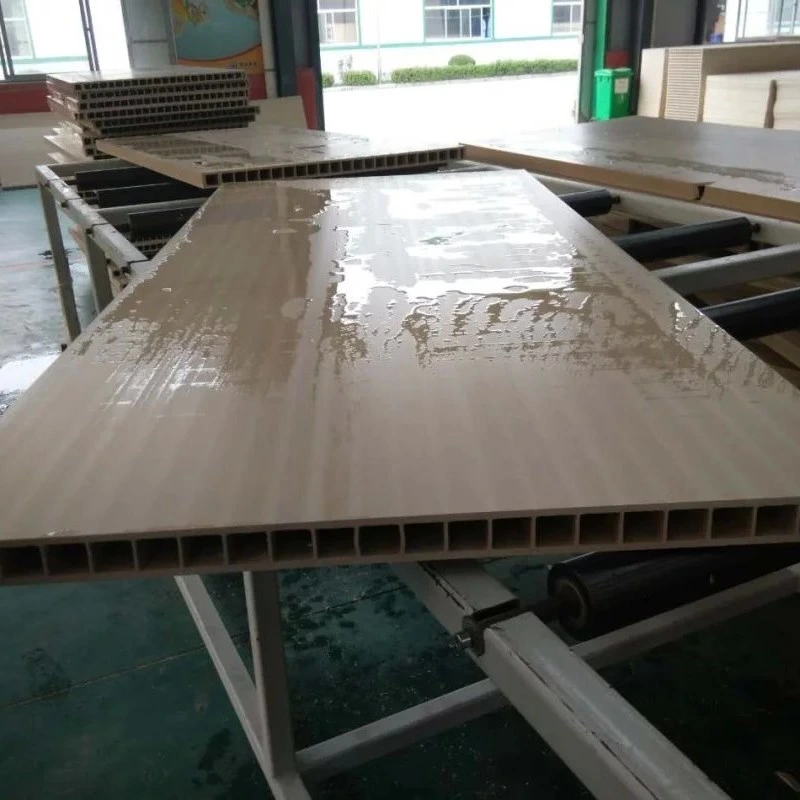

wpc pvc doors making machine/plastic recycle wood plastic composite extruder |

Component of wpc pvc doors making machine/plastic recycle wood plastic composite extruder

|

Instruction of wpc pvc doors making machine/plastic recycle wood plastic composite extruder

Description | Parameter |

Feed material | PVC+ assistant materials(also can add wood powder) |

Product size | (width600-900mm,thickness30-50mm) |

Production line speed | 0.8-1m/min |

Max. output | 350-500kg/h |

Outline size | 23×2.5×3 L×W×H(m),unsaturated |

Weight | 16T |

Total power | 255kw |

Actual energy consumption power | 210kw |

Consumed air | 0.4m3/min |

Atmospheric pressure | 0.6mpa |

Water cycle | 0.3m3/min |

Power | AC380V±10%,50HZ |

Water | Industrial water, no impurity, with filtration treatment, pressure: 0.4Mpa temperature: 14-25°C |

Work environment temperature | 0-40°C |

Production Flow of wpc pvc doors making machine/plastic recycle wood plastic composite extruder

Craft procedure Host machine extrusion→Vacuum calibrating→Haul off→Cutting→collecting→Convey→twin color stamping→drying→primer coating→levelling→painting→levelling→solidify forming→Convey→ Checking up→Packing→Finishing |

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support by Bureau Veritas.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Contact