PP PE Film Plastic Recycling Machine and Pelletizer

1. Belt conveyor with metal-detector

2. Compactor: pretreatment--grind, heat by friction, shrink, to promote feeding efficiency.

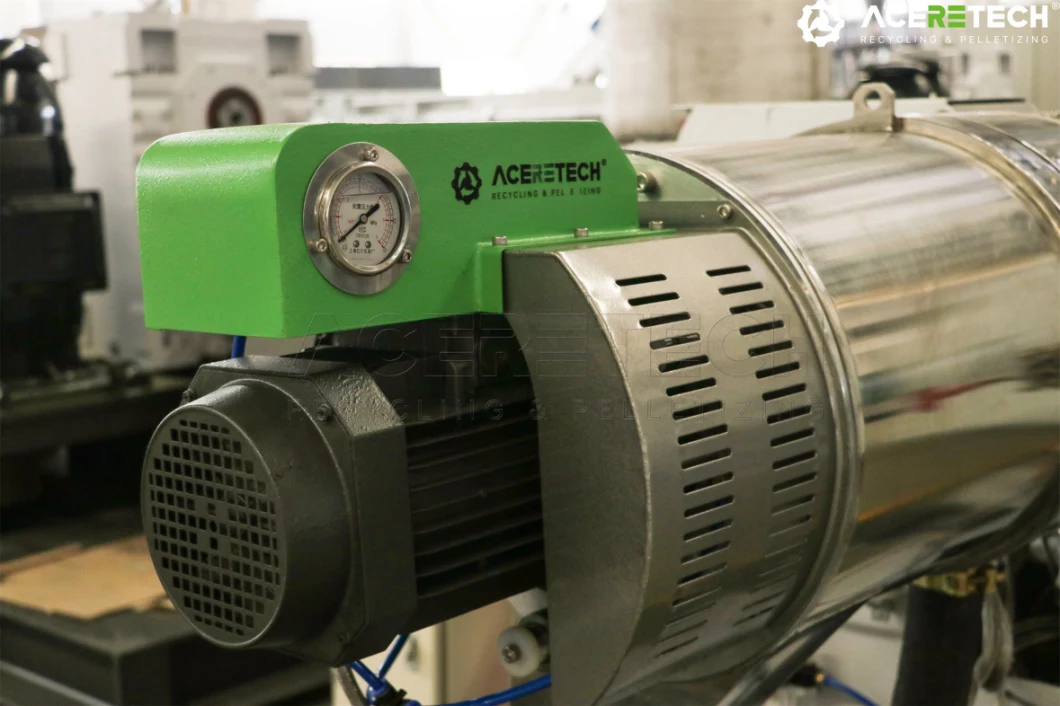

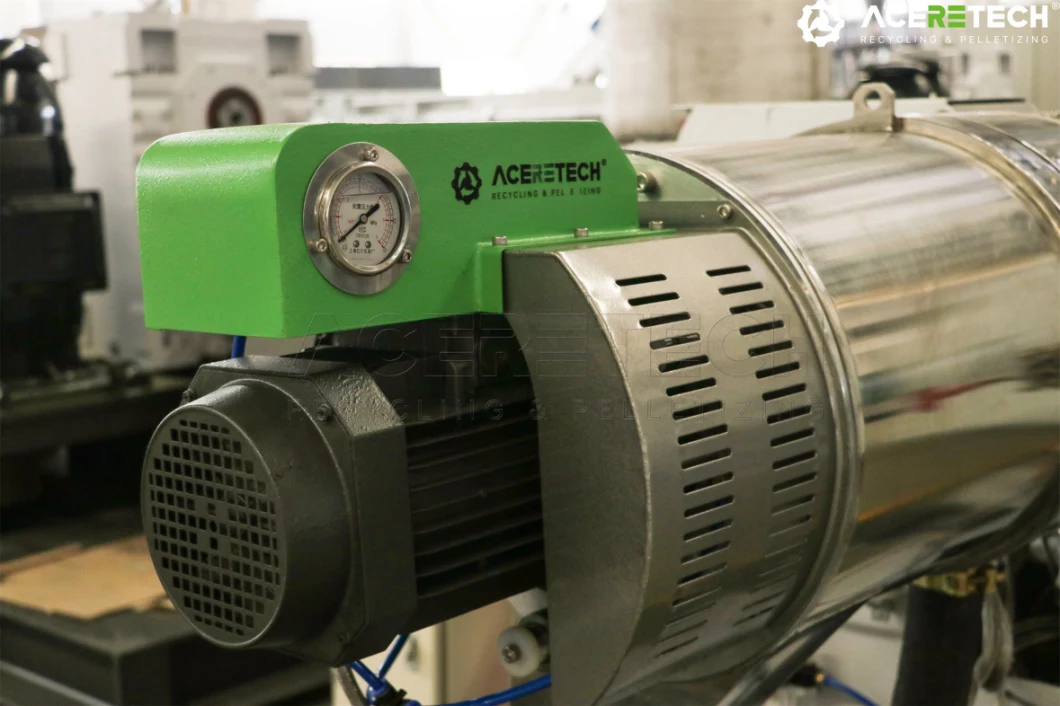

3. Plasticization with vacuum degassing:gentle melt with removing moisture and print.

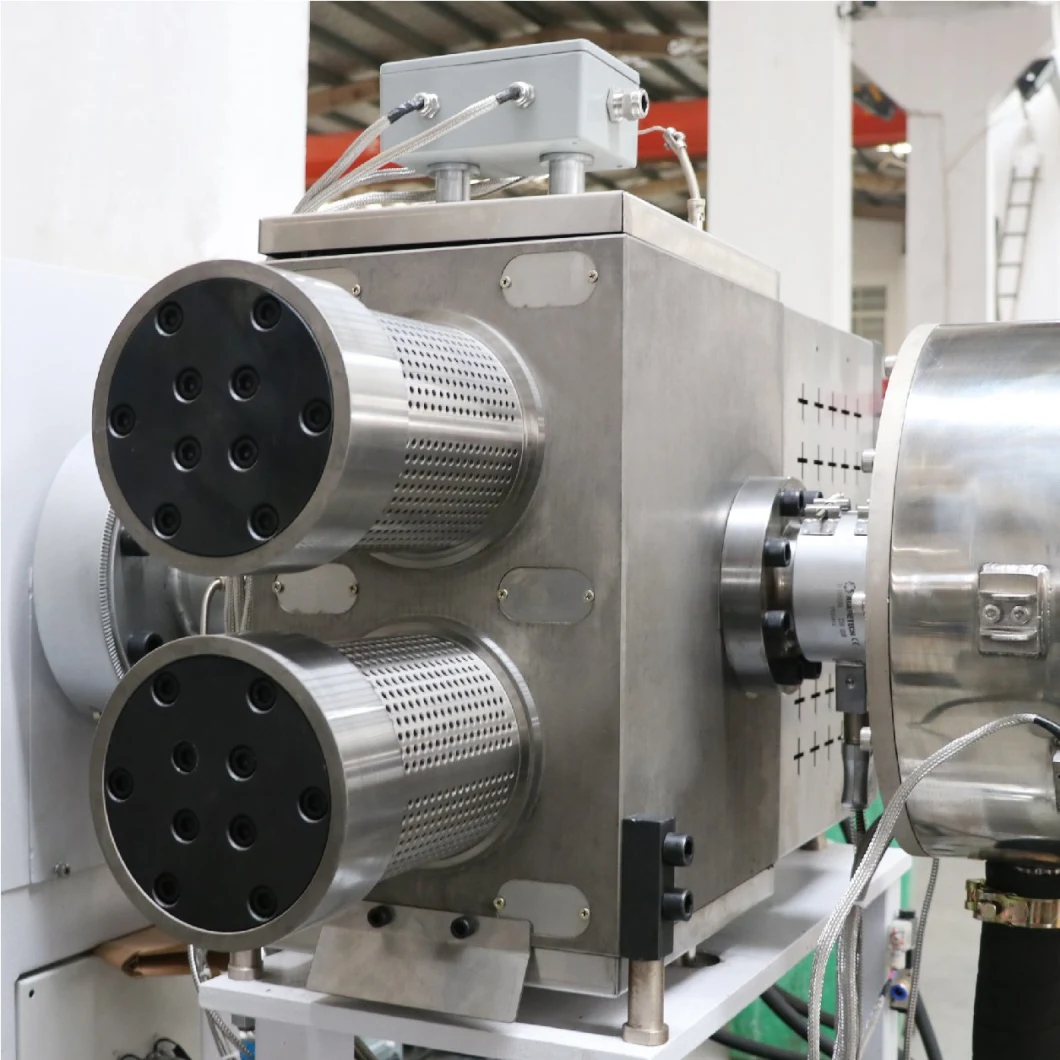

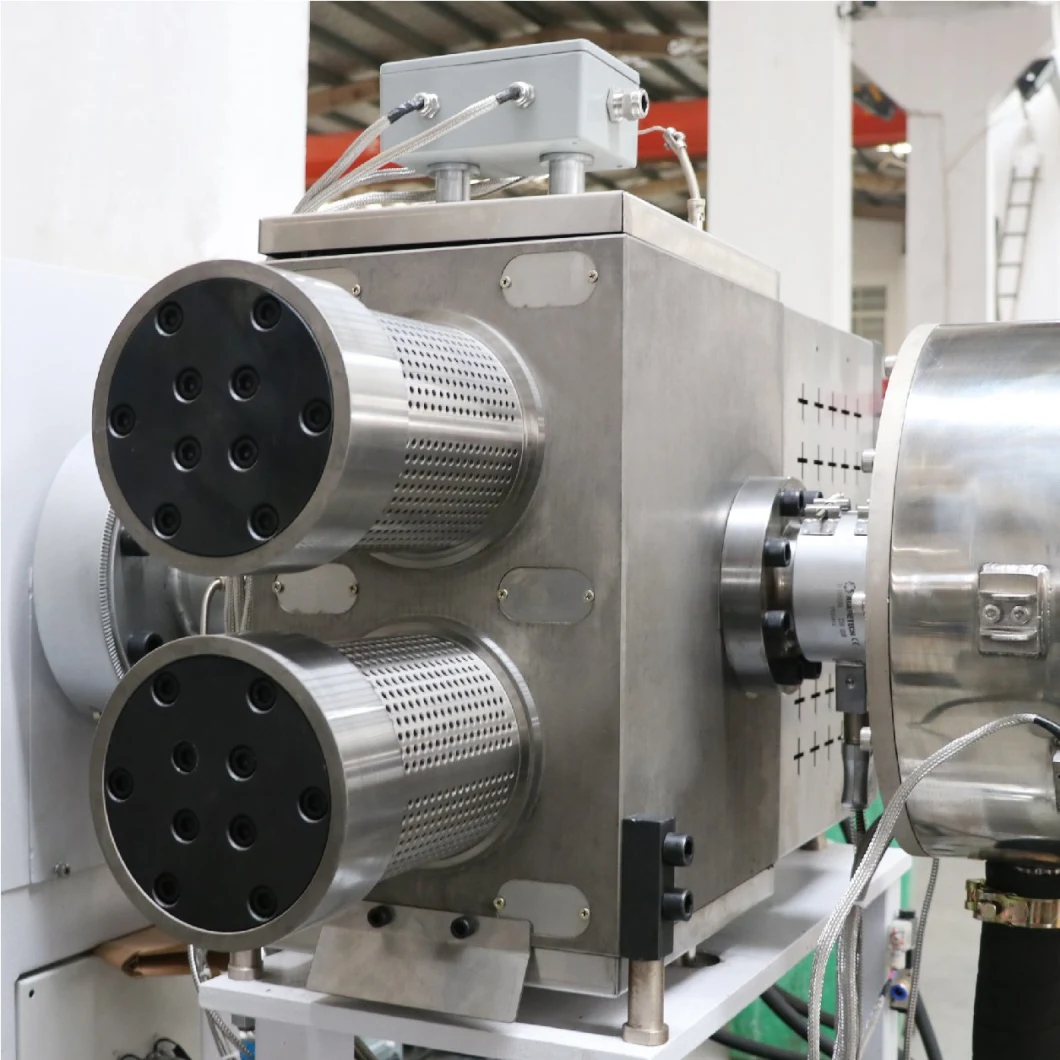

4. Melt filtration: to clean the melt. Plate-type, piston type, Self-cleaning type of filters.

5. Pelletizing: to make pellets, even size, automatic, with drying and packing system.

Main technical parameter:

Related Products

Innovative research and design team with 20-year experience in plastic recycling industry.

Would like to know about ACERETECH products, inquiry us now

Why Choose Aceretech

Innovative research and design team with 20-year experience in plastic recycling industry.

Jiangsu Aceretech Machinery CO.,LTD - Company Profile.

ACERETECH is a company specializing in the R&D and manufacturing of waste plastics recycling granulation equipment. The company combines recycling technology teams from Europe, Taiwan and the mainland, bringing the world's leading and mainstream recycling technology to all of our customers. And we always adhere to the people-oriented, integrity-based and technology-based.

ACERETECH has successfully entered into strategic cooperation agreements with a number of European companies to help us manufacture high-standard, high-demand equipment in China.

Aceretech can provide the Washing and Pelletizing Turn-key Solution to all the customers. Please contact the professional sales team from Aceretech, they will provide you with customized solutions. All the design drawings and technical specifications can be provided according to your request. Installation, Testing, and Training Aceretech can supply the engineer to customers' factories for installation, testing and training according to your needs. It will facilitate a better integration for the new factory and new machine. The engineer can offer training lessons in customer's factory during the installation, the customer could also send their engineer to Aceretech for training. The technicist from Aceretech will introduce all the parts of operation and maintenance equipment for customers' engineer. Aceretech will supply a detailed instruction manual for all the customers, the operation will be more convenient. Before delivery, Acerectch will also support you dimension drawings, it will ensure your operators are fully prepared for production, improve operational efficiencies. For this issue, please contact with the sales from Aceretech to arrange on-site work.

Typical products manufactured by ACERETECH are: High capacity performance Plastics Agglomerating and Re-granulating line for material of small bulk-density, Single-screw Extrusion and pelletization line with diameter-reducing screw structure for regular capacity but energy-saving demands, Single-screw extrusion and pelletization line for rigid waste plastic scraps, Twin-screw extruder, Shredders ans Granulators. Advantages of ACERETECH: 1. Innovative research and design team with 20-year experience in plastic recycling industry. 2. Complete sales system covering pre- and after-sales service. Engineers are available for commissioning work abroad. 3. Professional sales team with local language speaking ability of English, Spanish, Turkish and Russian.

Would like to know about ACERETECH, inquiry us now.

FAQ

Innovative research and design team with 20-year experience in plastic recycling industry.

HOW TO FIND KING MACHINE?

Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

Visit exhibition in different countries

Send King Machine an request and tell your basic inquiry

King Machine sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

If we can fullfill your request and you interested in our products, you may pay a visit to our site

The meaning of visiting supplier, because seeing is believing, we with our own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

By letter of credit, you can lock the delivery time easily.

After the factory visit, You can ensure the facticity of our bank account.

HOW TO ENSURE THE QUALITY!

In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

Each component before assembly needs strictly control by inspecting personnel.

Each assembly is in charged by a master who has working experience for more than 5 years

After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE !

After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

After the commissioning, we will package the equipment by standard export package for shipment.

According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

1. Belt conveyor with metal-detector

2. Compactor: pretreatment--grind, heat by friction, shrink, to promote feeding efficiency.

3. Plasticization with vacuum degassing:gentle melt with removing moisture and print.

4. Melt filtration: to clean the melt. Plate-type, piston type, Self-cleaning type of filters.

5. Pelletizing: to make pellets, even size, automatic, with drying and packing system.

Main technical parameter:

| Machinery size | Data of compactor | Data of single screw extruder | Throughput rate(Kg/hr) | |||

| Efficiency volume(Liter) | Motor power(Kw) | Diameter of screw(mm) | L/D | Motor power(Kw) | ||

| ACS300/80 | 300 | 37 | 80 | 36 | 45/55 | 160-220 |

| ACS500/100 | 500 | 55 | 100 | 36 | 90/110 | 300-380 |

| ACS800/120 | 800 | 90 | 120 | 36 | 132 | 450-480 |

| ACS1000/140 | 1000 | 110 | 140 | 36 | 160/185 | 500-650 |

| ACS1200/160 | 1200 | 132 | 160 | 34 | 220/250 | 800-1000 |

| ACS1400/180 | 1400 | 315 | 180 | 34 | 315 | 1000-1200 |

Related Products

Innovative research and design team with 20-year experience in plastic recycling industry.

Would like to know about ACERETECH products, inquiry us now

Why Choose Aceretech

Innovative research and design team with 20-year experience in plastic recycling industry.

Jiangsu Aceretech Machinery CO.,LTD - Company Profile.

ACERETECH is a company specializing in the R&D and manufacturing of waste plastics recycling granulation equipment. The company combines recycling technology teams from Europe, Taiwan and the mainland, bringing the world's leading and mainstream recycling technology to all of our customers. And we always adhere to the people-oriented, integrity-based and technology-based.

ACERETECH has successfully entered into strategic cooperation agreements with a number of European companies to help us manufacture high-standard, high-demand equipment in China.

Aceretech can provide the Washing and Pelletizing Turn-key Solution to all the customers. Please contact the professional sales team from Aceretech, they will provide you with customized solutions. All the design drawings and technical specifications can be provided according to your request. Installation, Testing, and Training Aceretech can supply the engineer to customers' factories for installation, testing and training according to your needs. It will facilitate a better integration for the new factory and new machine. The engineer can offer training lessons in customer's factory during the installation, the customer could also send their engineer to Aceretech for training. The technicist from Aceretech will introduce all the parts of operation and maintenance equipment for customers' engineer. Aceretech will supply a detailed instruction manual for all the customers, the operation will be more convenient. Before delivery, Acerectch will also support you dimension drawings, it will ensure your operators are fully prepared for production, improve operational efficiencies. For this issue, please contact with the sales from Aceretech to arrange on-site work.

Typical products manufactured by ACERETECH are: High capacity performance Plastics Agglomerating and Re-granulating line for material of small bulk-density, Single-screw Extrusion and pelletization line with diameter-reducing screw structure for regular capacity but energy-saving demands, Single-screw extrusion and pelletization line for rigid waste plastic scraps, Twin-screw extruder, Shredders ans Granulators. Advantages of ACERETECH: 1. Innovative research and design team with 20-year experience in plastic recycling industry. 2. Complete sales system covering pre- and after-sales service. Engineers are available for commissioning work abroad. 3. Professional sales team with local language speaking ability of English, Spanish, Turkish and Russian.

Would like to know about ACERETECH, inquiry us now.

FAQ

Innovative research and design team with 20-year experience in plastic recycling industry.

HOW TO FIND KING MACHINE?

Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

Visit exhibition in different countries

Send King Machine an request and tell your basic inquiry

King Machine sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

If we can fullfill your request and you interested in our products, you may pay a visit to our site

The meaning of visiting supplier, because seeing is believing, we with our own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

By letter of credit, you can lock the delivery time easily.

After the factory visit, You can ensure the facticity of our bank account.

HOW TO ENSURE THE QUALITY!

In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

Each component before assembly needs strictly control by inspecting personnel.

Each assembly is in charged by a master who has working experience for more than 5 years

After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE !

After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

After the commissioning, we will package the equipment by standard export package for shipment.

According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.