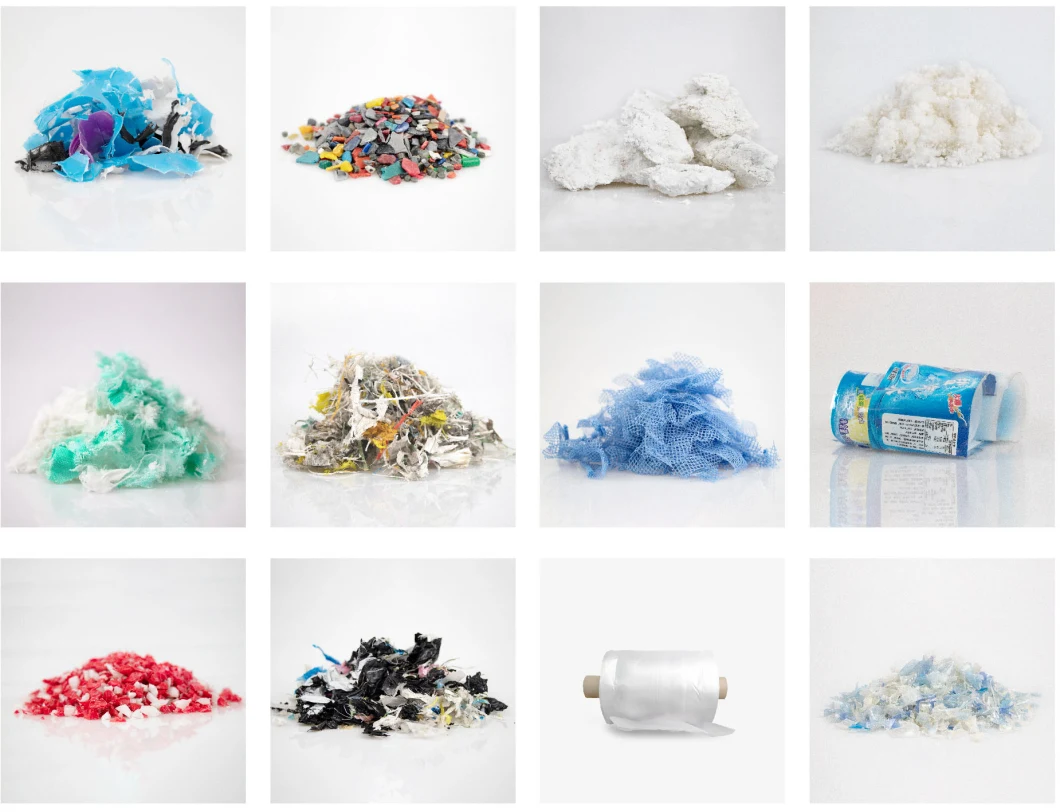

Aceretech's high efficiency, one-step plastic recycling machine ACS-H is designed for the reprocessing of PE polyethylene (HDPE, LDPE, LLDPE), PP polypropylene flexible packaging material (BOPP, OPP), PET film, printed and non-printed, and foamed material such as EPE EPP EPS, also filament, raffia, nylon, etc. This compactor integrated pelletizing system eliminates the need of pre-cutting the material, requires less space and energy consumption while producing high quality plastic pellets at a productive rate.

1) Simple design, user-friendly operation.

2) Siemens original motors, ABB/Schneider converts.

3) Siemens PLC, Celduc solid relay, Gefren pressure sensors, Omron Temperature controllers, LS air switch.

4) Lower investment cost for a high quality and durable machine.

5) Low energy consumption, High output capacity.

6) Aceretech produces 10 sets of ACS-H series compacting pelletizing machines per month. Usual delivery time: 60 days.

7) Engineers are available to do commissioning work abroad.

FOR MORE DETAILS OF plastic recycling machine PLEASE FEEL FREE TO CONTACT US.

ABS flakes → ABS pellets HDPE bottle flakes→ HDPE pellets PET Zip → PET pellets PET flakes→ PET pellets

ALL these materials can be recycled by our machine. PLEASE FEEL FREE TO CONTACT US if you have any other materials to be recycled.

Machine Details

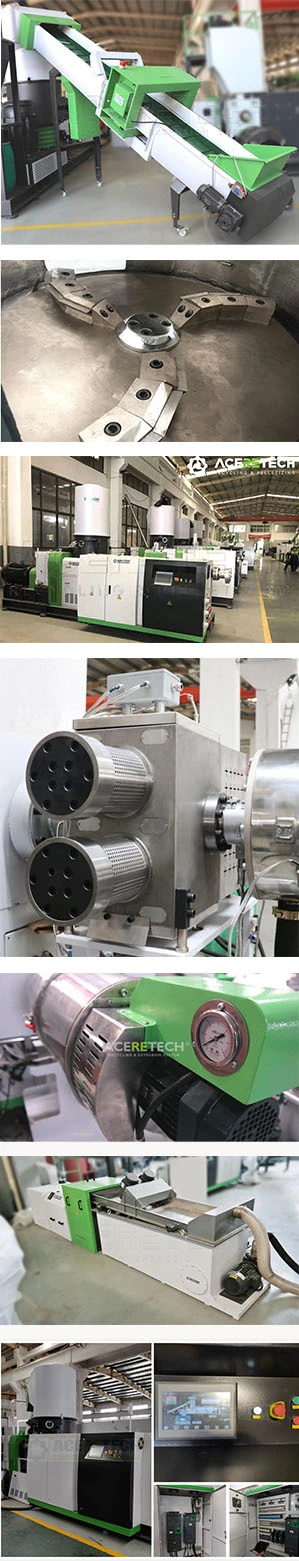

| Belt conveyorPlastic film, bags, filament, raffia are conveyed by belt conveyor up into the compactor. Hauling roller for feeding rolls of film. Speed adjusted by ABB/Schneider inverter.

Metal detecotor as an option, to detect and notify to remove metals. |

Compactor / AgglomeratorThe rotatory blades of compactor will cut up incoming scraps. Frictional heating which caused by high speed rotatory blades will heat and let scraps shrinking just below their agglomerating point. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder. | |

Plasticization (Extruder)A specialized single-screw extruder applied to gently melt the pre-compacted material. The plastic scraps will be well melted, plasticized in the extruder. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiently, especially suitable for heavy printed film and material with much moisture. | |

| Melt filtration The requirements on the filter technology depend on the characteristics of the input material as well as the planned use of final granules. Regular single-plate/piston double-station screen changer or non-stop double-plate/ piston four-station can be installed on the end of the extruder to present significant filtration performance. | |

Water-ring Die-face cutting systemWater-ring die-face/Strand cutting methods are usually adopted. In water-ring die-face cutting system, the rotary cutting blades will be pneumatically fit completely and closely to the die-face surface to ensure efficient cutting. Rotary speed of the blades is automatically adjusted by module system according to melt pressure at the die face. | |

Dewatering systemAdvanced vibration sieve combining with horizontal centrifugal presents high performance of drying. | |

Electric control systemSiemens PLC intelligent control system, user-friendly operation. International famous brands: Siemens, Celduc, Gefren, Omron, etc. |

Main Technical Parameter

| Machinery size | Data of compactor | Data of single screw extruder | Throughput rate(Kg/hr) | |||

| Efficiency volume(Liter) | Motor power(Kw) | Diameter of screw(mm) | L/D | Motor power(Kw) | ||

| ACS-H300/80 | 300 | 37 | 80 | 36 | 45/55 | 150-200 |

| ACS-H500/100 | 500 | 55 | 100 | 36 | 90/110 | 300-350 |

| ACS-H800/120 | 800 | 90 | 120 | 36 | 132 | 400-450 |

| ACS-H1000/140 | 1000 | 110 | 140 | 36 | 160/185 | 500-650 |

| ACS-H1200/160 | 1200 | 132 | 160 | 34 | 220/250 | 800-1000 |

| ACS-H1400/180 | 1400 | 160 | 180 | 34 | 315 | 1000-1200 |

ACERETECH Service

Before-sale

a. Introduce products and applications detain

b. Recommend suitable solution

c. Provide with reference information

d. Offer lab for test

During Manufacturing

a. Provide with layout and engineering conditions

b. Inform the project processing status

c. Offer other documents

After-sale

a. Provide with installation, commissioning and training

b. Register and record customer information

c. Offer spare parts

d. Provide with necessary technical support for new application

e. Visit customer regularly and correct information

Online Services

ACERETECH services Online gives you fast and easy online access to your installed base to order your ACERETECH recycling machine original spare parts and explore the Options & Upgrades relevant for your line.

It is a user-friendly interface, available 24/7, in 4 languages. And is your one-stop online shopping. Designed to make your life easier in your day to day business. It will help you to improve your line and maintain its performance.

About US--ACERETECH MACHINERY

ACERETECH is a creative company, focusing on the technology R&D of Plastic recycling and providing the equipments and solutions for Plastics recycling, washing and re-granulation.

ACERETECH's Plastic recycling technology mainly applied in the field of waste plastics regrinding, washing and re-granuling.

Thanks to the R&D ability and well-understanding industries' experience, ACERETECH can provide the customized Plastic recycling solutions to customers.

Typical productions ACERETECH'S can provide are: High capacity performance Plastics Agglomeration and pelletizing machine for film recycling and pelletizing process, single screw extrusion and pelletizing line with enforciing feeder for regular capacity but energy-saving demands, single screw extrusion and pelletizing line for rigid waste plastics recycling and the line of crushing, washing for wasting for waste and impurity plastics pre-processing.

Advantages of ACERETECH:

- Specialized R&D team involved in Plastics Recycling Industries more than 20 years.

- Ability to provide the customized plastics recycling solutions;

- Complete sales system covering the pre-sales, sales and after sales job;

- Professional sales team with local language speaking ability for English, Spanish Turkish and Russian markets.

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

a. If we can fulfill your request and you interested in our products, you may pay a visit to the ACERETECH Machine site.b. The meaning of visiting supplier, because seeing is believing, ACERETECH Machine with own manufacture and developed& research team, we can send you engineers and make sure you are after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY!

a. In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

b. Each component before assembly needs strict control by inspecting personnel.

c. Each assembly is in charge by a master who has working experience for more than 15 years

d. After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF ACERETECH MACHINE!

a. After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

b. After the commissioning, we will package the equipment by the standard export package for shipment.

c. According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

d. Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

Why choose us

a. Lower investment cost for a high quality and durable machine;

b. Low energy consumption with high production output;

c. Overseas installation and training are available;

d. Machine warranty with spares in stocking and in-time delivery; e. Fast machine delivery and installation: AceRetech produces on an average of 10 sets of plastic machines per month and can deliver the machine faster than most manufacturers. The regular delivery time of an AceRetech recycling machine is 60 days.