PLASTIC PVC PIPE EXTRUSION Machine

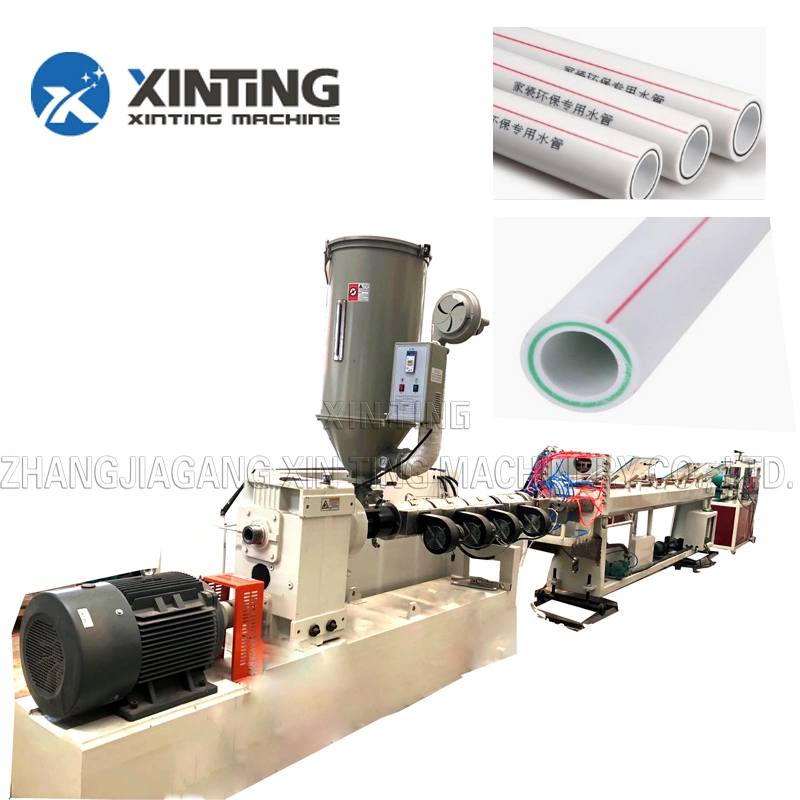

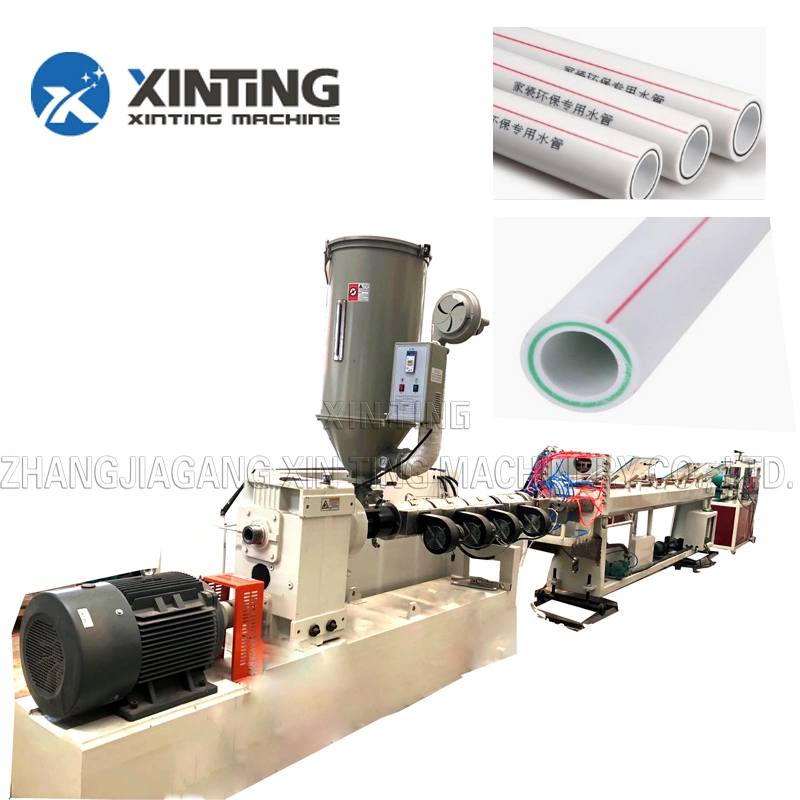

HDPE / PE PPR Pipe is mainly used for in the area of agricultural water supply system, architectural water supply and draiange system, pavement of cables and gas supply etc.

The basic HDPE / PE Pipe Production Line consists of

1. Color Mixer ( for raw material preparation)

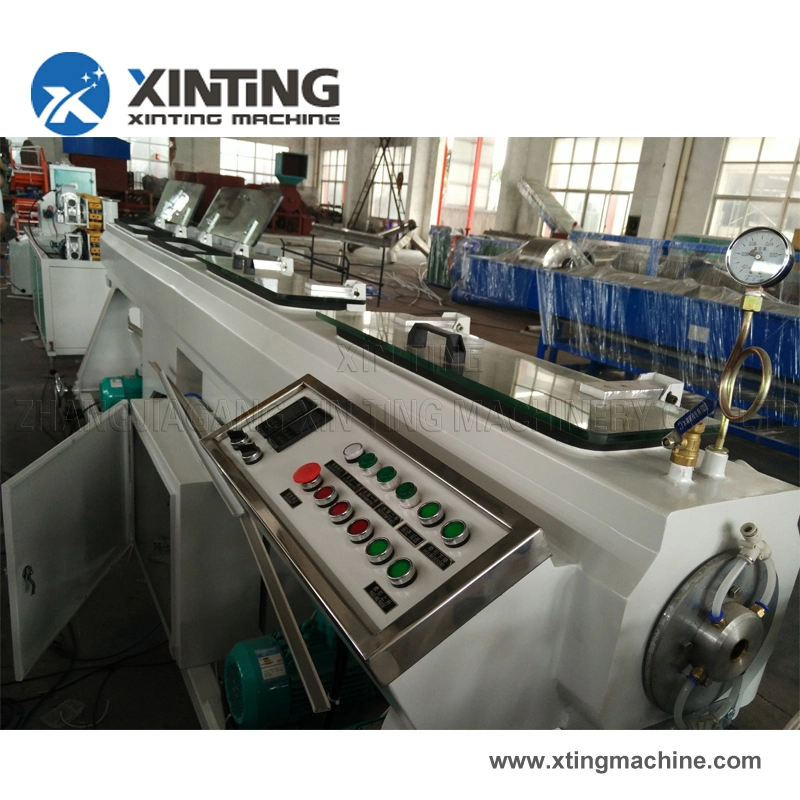

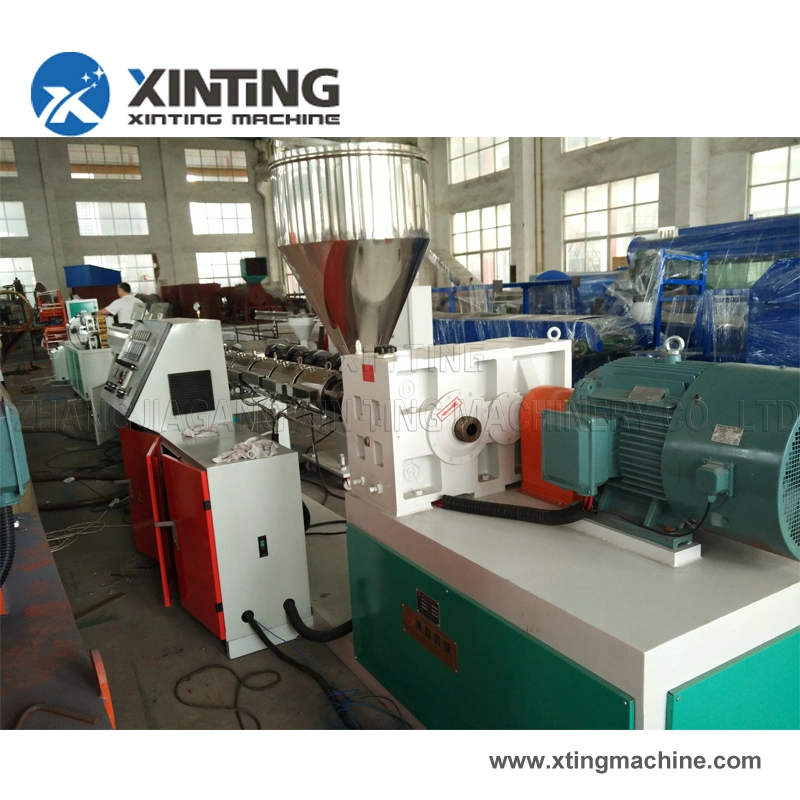

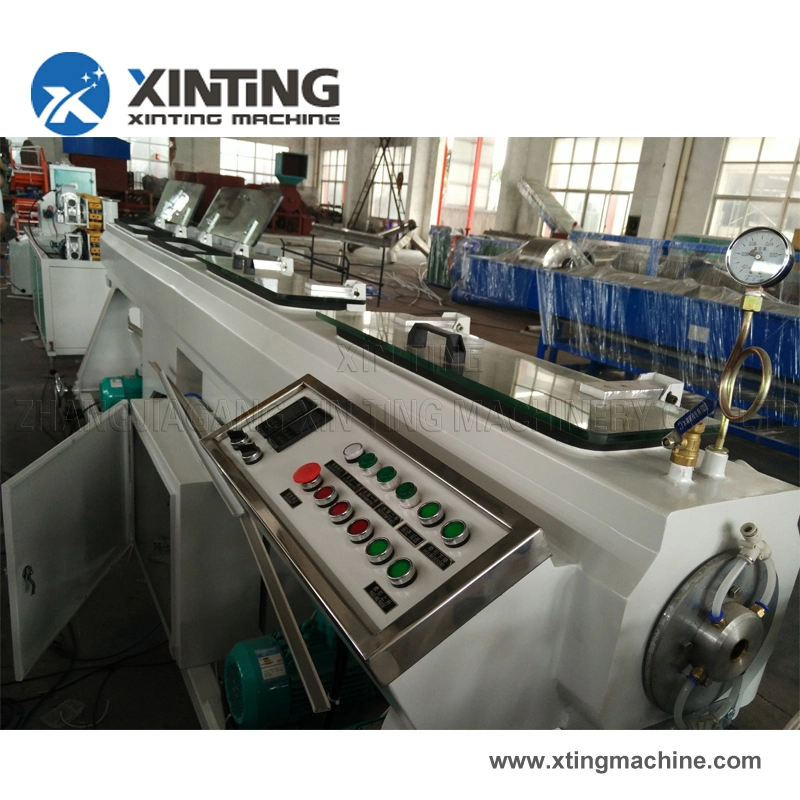

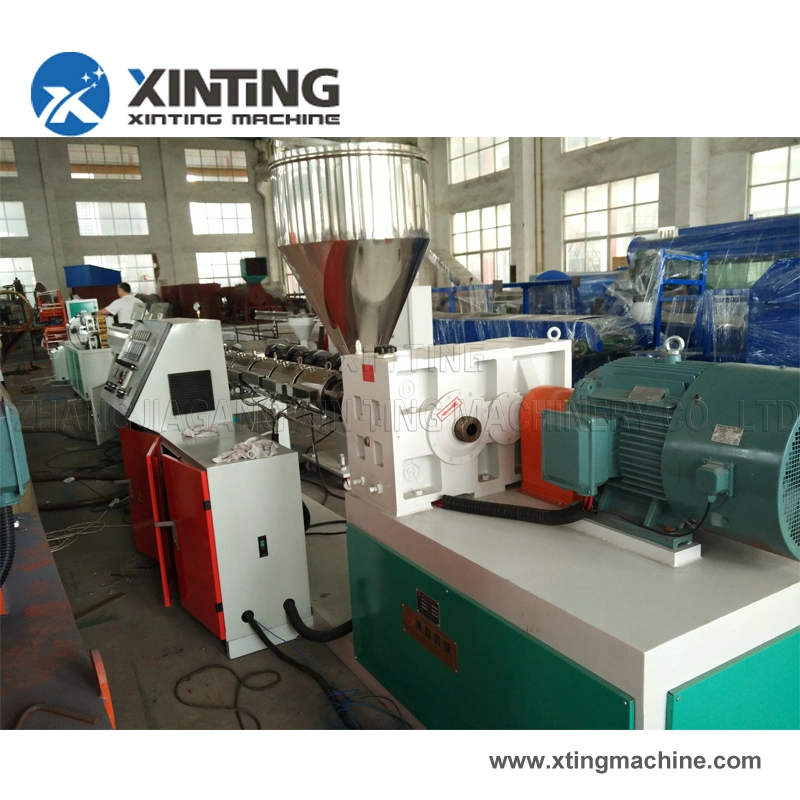

2. Single Screw Extruder

3. Extrusion Mold

4. Vacuum Tank

5. Cooling Tank

6. Haul Off Machine

7. Cutting Machine

8. Stacker ( for 110mm upto 1200mm)

9. Winding Machine ( for pipe diameter 16-63mm and 75-110mm)

10. Shredder and Crusher ( for waste pipe treatment, the recycled PE material could produce pipe again.)

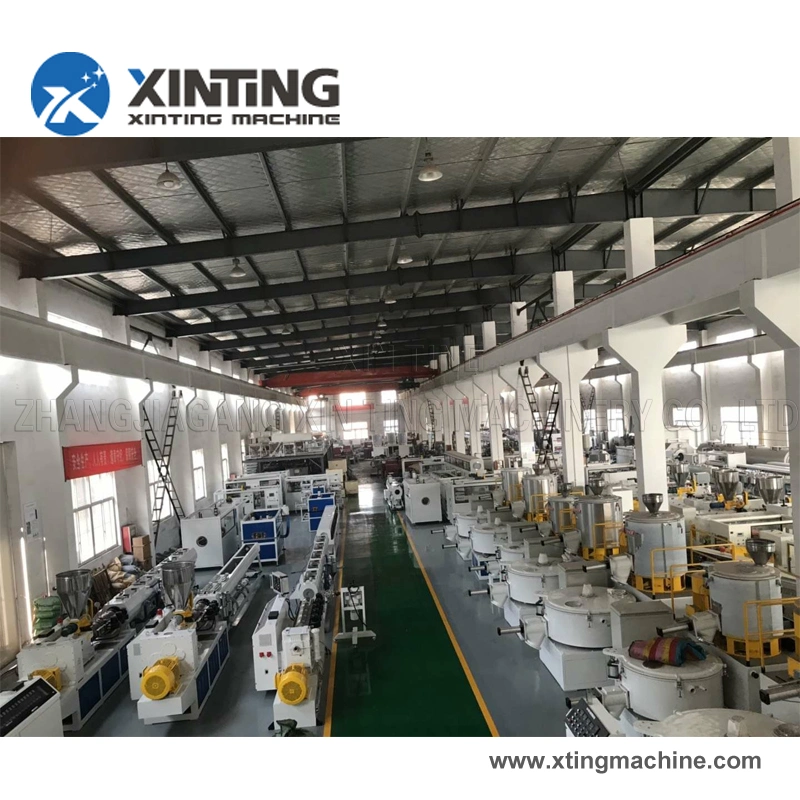

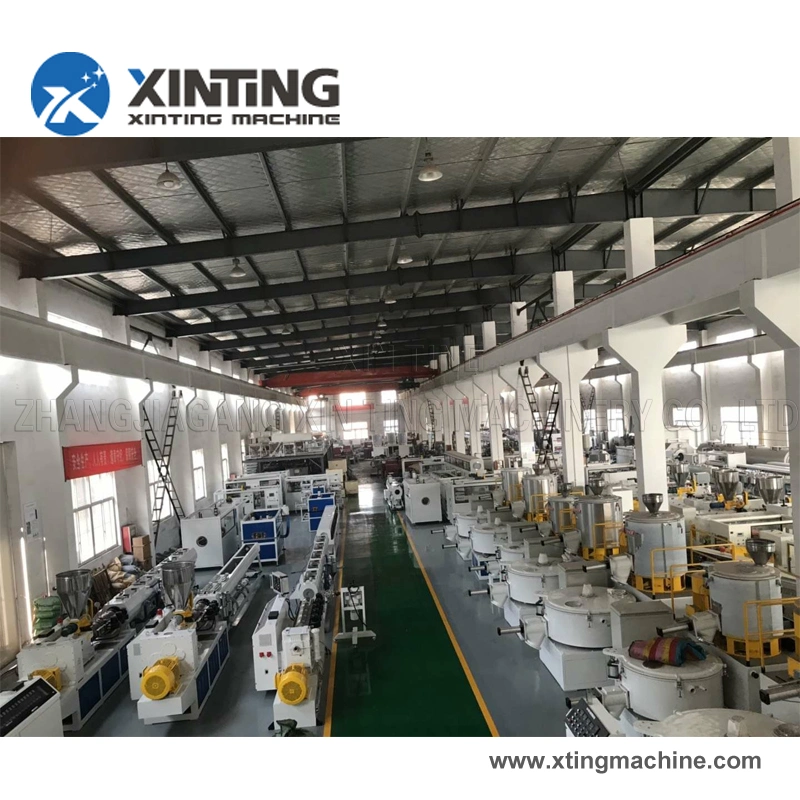

Our HDPE / PE PPR Pipe Production Line has the features as below:

1. Good components: Siemens Beide main motor, ABB inverter, Eurotherm DC regulator, Siemens & Schneider low voltage electrics, Omron temperature controller

2. Good design and good outlook: We design the machine for easier operation and stable performance. The haul off machine and cutter is fully closed for safety purpose. Planetary socket is using in some machines for wire connection.

3. Our engineers and technicians have more than 10 years experince, they know pipe machine well and make good pipe machine.

2.Features of PE pipe production line

3. Main technical parameter of PE pipe production line

The basic HDPE / PE Pipe Production Line consists of

1. Color Mixer ( for raw material preparation)

2. Single Screw Extruder

3. Extrusion Mold

4. Vacuum Tank

5. Cooling Tank

6. Haul Off Machine

7. Cutting Machine

8. Stacker ( for 110mm upto 1200mm)

9. Winding Machine ( for pipe diameter 16-63mm and 75-110mm)

10. Shredder and Crusher ( for waste pipe treatment, the recycled PE material could produce pipe again.)

Our HDPE / PE PPR Pipe Production Line has the features as below:

1. Good components: Siemens Beide main motor, ABB inverter, Eurotherm DC regulator, Siemens & Schneider low voltage electrics, Omron temperature controller

2. Good design and good outlook: We design the machine for easier operation and stable performance. The haul off machine and cutter is fully closed for safety purpose. Planetary socket is using in some machines for wire connection.

3. Our engineers and technicians have more than 10 years experince, they know pipe machine well and make good pipe machine.

Technical parameters:

Model | Pipe diameter | Extruder. | Max. output (kg/h) | Total installed power (KW) | Lenght of production line(m) |

PE-32 | Φ4-32 | SJ-45/30 SJ-25/25 | 30-120 | 45 | 28 |

PE-63 | Φ20-63 | SJ-60/33 SJ-25/25 | 120-220 | 100 | 36 |

PE-110 | Φ20-110 | SJ-65/33 SJ-30/25 | 150-250 | 120 | 39 |

PE-160 | Φ63-160 | SJ-65/33 SJ-30/25 | 120-270 | 150 | 43 |

PE-250 | Φ75-250 | SJ-75/33 SJ-30/25 | 280-400 | 230 | 45 |

PE-450 | Φ110-450 | SJ-90/33 SJ-30/25 | 450-600 | 350 | 65 |

PE-630 | Φ315-630 | SJ-120/33 SJ-30/25 | 700-950 | 550 | 75 |

PE-800 | Φ400-800 | SJ-90/33 SJ-105/33 | 800-1200 | 700 | 75 |

| 1 | The optimum spiral bush highly improves the output of extruder |

| 2 | Accurate temperature control system ensures material melting performance |

| 3 | Unique screw design achieves better plasticizing and high quality products |

| 4 | Precisely designed gearbox with a high torsion guarantees stable running |

| 5 | Advanced PLC operation system realizes synchronization and high quality products |

| 6 | Adopt automatic water temperature &level control and special independent filters on both vacuum and cooling tanks |

| 7 | Offer stable haul-off unit with 2-12 caterpillars |

| 8 | Provide saw &chip free cutting options |

| 9 | Low energy consumption, excellent performance, and easy maintenance |

3. Main technical parameter of PE pipe production line

| Model | Pipe range(mm) | Extruder Model |

| XT-63 | φ16-63 | SJ65/33 |

| XT-110 | φ20-110 | SJ65/33 |

| XT-160 | φ40-160 | SJ75/33 |

| XT-250 | φ63-250 | SJ75/33 |

| XT-315 | φ110-315 | SJ90/33 |

| XT-450 | φ160-450 | SJ90/33 |

| XT-630 | φ280-630 | SJ120/33 |

| XT-800 | φ450-800 | SJ150/33 |

| XT-1200 | φ710-1200 | SJ150/33 |

| XT-1600 | φ900-1600 | SJ150/33 |