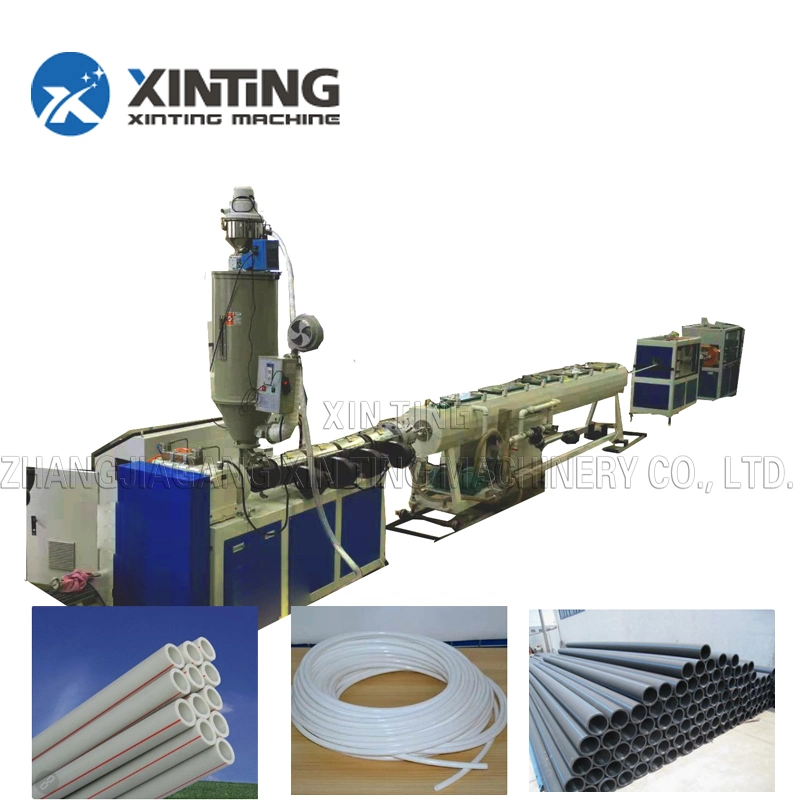

Plastic PPR Pipe Extrusion Machine/production line /making machine

Features of product:

1. Equipped with polyolefin purposed single-screw extruder; it has the characters of quick plasticizing, high efficiency and so on.

2. The specially designed co-extrusion die head is reasonable in flow channel, smooth in both internal and external walls, and small in internal stress.

3. Pipe diameter is among 20-160mm and production speed reaches to 18m/min.

4. One unit serves several purposes. It can produce common PP-R, Nanometer anti-bacteria pipe, PE-RT and PE-X.

5. If added one co-extrusion engine and die on original base, it can produce PP-R fiberglass reinforced composite pipe

Process line:

2. The specially designed co-extrusion die head is reasonable in flow channel, smooth in both internal and external walls, and small in internal stress.

3. Pipe diameter is among 20-160mm and production speed reaches to 18m/min.

4. One unit serves several purposes. It can produce common PP-R, Nanometer anti-bacteria pipe, PE-RT and PE-X.

5. If added one co-extrusion engine and die on original base, it can produce PP-R fiberglass reinforced composite pipe

Process line:

Raw material +master batches → mixing→vacuum feeding → material dryness → single screw extruder → single screw extruder → singlescrew extruder → color Line extruder → co-extrusion mould → calibrator → spray vacuum calibration tank → spray coolingwater tank → word printer → haul-off → no-dust cutter → pipe rack→finished product

Model | Screw diameter | L/D | Extruder Qty (set) | Pipe range (mm) | Capacity (kg/h) | Total power (kw) | Line length |

PPR pipe 16-63mm | 65mm | 28:1 or 30:1 | 1 | 16-63 | 100-150 | 52 | 18 |

PPR pipe 63-160mm | 65mm or 75mm | 28:1 or 30:1 | 1 | 63-160 | 120-180 | 67 | 22 |

PPR glass fiber pipe 20-63mm | 65mm+ 50mm or 65mm | 28:1 or 30:1 | 2 or 3 | 20-63 | 120-220 | 95 | 20 |

Technical parameters:

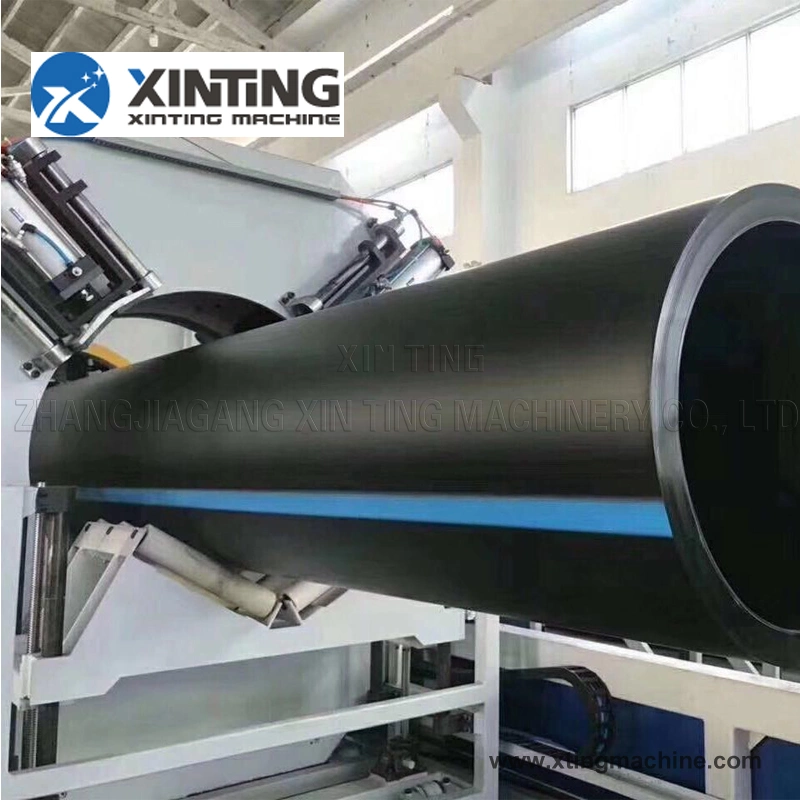

Model | Pipe diameter | Extruder. | Max. output (kg/h) | Total installed power (KW) | Lenght of production line(m) |

PE-32 | Φ4-32 | SJ-45/30 SJ-25/25 | 30-120 | 45 | 28 |

PE-63 | Φ20-63 | SJ-60/33 SJ-25/25 | 120-220 | 100 | 36 |

PE-110 | Φ20-110 | SJ-65/33 SJ-30/25 | 150-250 | 120 | 39 |

PE-160 | Φ63-160 | SJ-65/33 SJ-30/25 | 120-270 | 150 | 43 |

PE-250 | Φ75-250 | SJ-75/33 SJ-30/25 | 280-400 | 230 | 45 |

PE-450 | Φ110-450 | SJ-90/33 SJ-30/25 | 450-600 | 350 | 65 |

PE-630 | Φ315-630 | SJ-120/33 SJ-30/25 | 700-950 | 550 | 75 |

PE-800 | Φ400-800 | SJ-90/33 SJ-105/33 | 800-1200 | 700 | 75 |

Our HDPE / PE PPR Pipe Production Line has the features as below:

1. Good components: Siemens Beide main motor, ABB inverter, Eurotherm DC regulator, Siemens & Schneider low voltage electrics, Omron temperature controller

2. Good design and good outlook: We design the machine for easier operation and stable performance. The haul off machine and cutter is fully closed for safety purpose. Planetary socket is using in some machines for wire connection.

3. Our engineers and technicians have more than 10 years experince, they know pipe machine well and make good pipe machine.