Specification of high speed mixing

plastic material high speed hot mixer , SRL-W plastic horizontal mixter , plastic mixer , plastic high speed mixter

1.composed of high speed hot mixer, cold mixer... 2.mixing fast and even 3.easily cleaning, compact.

Mainly composed of high speed hot mixer, cold mixer, and electric control components etc. It is widely used in drying mixing blending and cooling the powder, liquid, granulate of plastics, rubber, dyestuffs, foodstuffs, chemical, Caco3 etc.

plastic material high speed hot mixer ,SRL-W plastic horizontal mixter , plastic mixer , plastic high speed mixter

1.It is used in mixing, drying, coloring and other processing. It is the most ideal equipment for producing shaped plastic material and plastic.

2. The technology of the main shaft sealed apparatus has got the national patent. ( patent number ZL96Z430641) with electric and steam heating functions.

3. Two layer of sealing technology is adopted in the pot cover. The opening of the heating mixed cover adopted the air opening device and the opening of the cooling mixed cover adopted hydraulic pressure control system.

4. The electrical control section with the programmable logic control adopted well-known imported meters and control components.

5.It is equipped with the pulse dust-cleaning recovery device.

6. The blades have been passed the test of the dynamic and static balance testing machine

7.you may choose the simple and easy feeding system.

Features of high speed mixing

The technology of sealing mainshaft is given the state patent.

The technology of two layers of sealing is adopted in its pot cover.

It has self-friction heating and electric heating modes.

The discharging mode shave the temperature-automatic control and the manual conrol.

Its blades are made of stainless steel. They passed the test of dnamic balance and static equilibrium.

Its electric control section adopts famous control components and temperature-control meters.

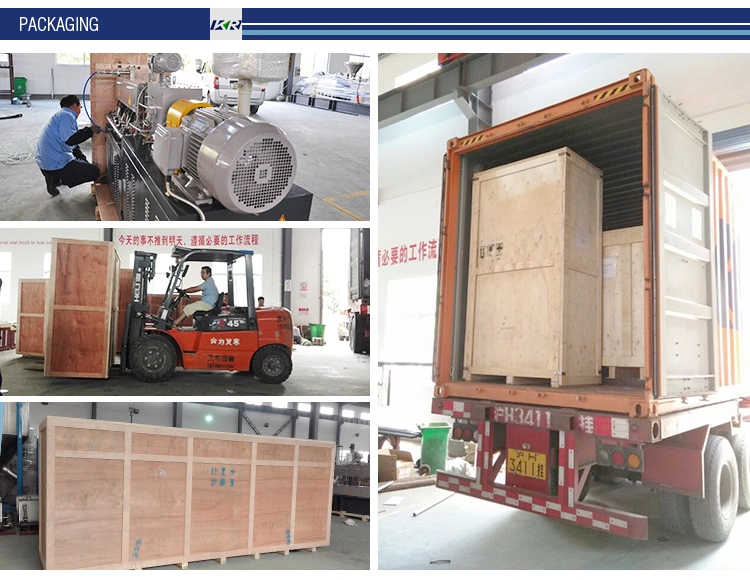

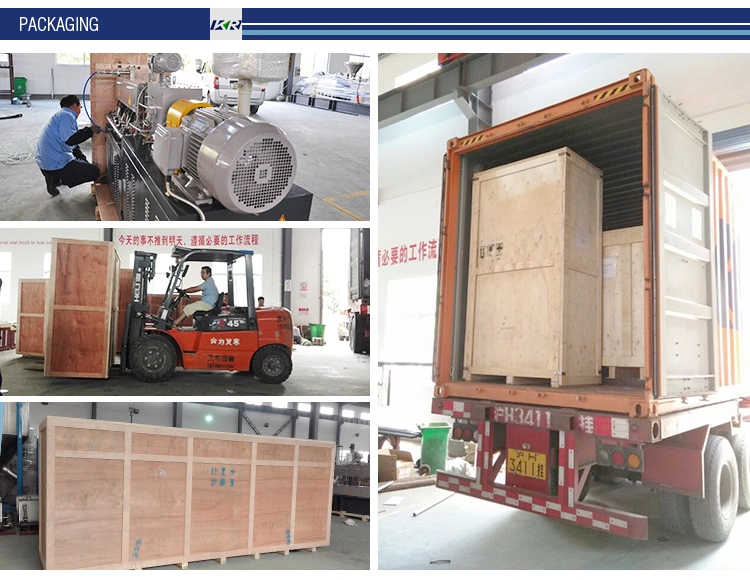

Packing

The mixer unit first wraped with film and packed in wooden cases in case shipping damange

Company Information

Kairong group , headquartered in Nanjing, China, is a global manufacturing and trading company in the field of high-performance plastics and rubber processing equipment , extrusion solutions, masterbatch and compounding, etc. Its unit Nanjing Haisi Extrusion Company is a prefessional manufacturer of twin screw extruder, single screw extruder ,two stage extruder and its related auxiaries. We tailor solutions from raw materials, materials processing equipment, to injection for different customers. Each Kairong solution is designed , manufactured, and commissioned by experienced teams of professionals engineers and aftersales staffs.

Kairong group offers raw materials, Mixing and conveying unit, extrusion technology, recycling unit, profile extrusion etc. We offer whole plant ,even turnkey solution to meet different customers' requirements.

Kairong Group believes that " High quality and profession service will bring bright future "

| model/ Item | Gross Capacity(L) | Effective Volume(L) | Motor Power(kw) | Spindle Speed(r/min) | Heating Mode | Unloading Mode | |

| SHR-5A | 5 | 3 | 1.2 | 1400 | Self friction | Manual | |

| SHR-10A | 10 | 7 | 2.2/3.2 | 750/1500 | |||

| SHR-25A | 25 | 17.5 | 5.5 | 1440 | electrical heating | 2kw | pneumatic |

| SHR-50A | 50 | 30 | 42196 | 750/1500(510/1013) | 4kw | ||

| SHR-100A | 100 | 75 | 14/22 | 525/1050(650/1300) | 6kw | ||

| SHR-200A | 200 | 150 | 30/42 | 490/980 | 6kw | ||

| SHR-300A | 300 | 225 | 40/55 | 480/964 | 9kw | ||

| SHR-500A | 500 | 375 | 47/67 | 441/886 | 9kw | ||

| SHR-800A | 800 | 560 | 83/110 | 330/660 | Self friction | ||

plastic material high speed hot mixer , SRL-W plastic horizontal mixter , plastic mixer , plastic high speed mixter

1.composed of high speed hot mixer, cold mixer... 2.mixing fast and even 3.easily cleaning, compact.

Mainly composed of high speed hot mixer, cold mixer, and electric control components etc. It is widely used in drying mixing blending and cooling the powder, liquid, granulate of plastics, rubber, dyestuffs, foodstuffs, chemical, Caco3 etc.

plastic material high speed hot mixer ,SRL-W plastic horizontal mixter , plastic mixer , plastic high speed mixter

1.It is used in mixing, drying, coloring and other processing. It is the most ideal equipment for producing shaped plastic material and plastic.

2. The technology of the main shaft sealed apparatus has got the national patent. ( patent number ZL96Z430641) with electric and steam heating functions.

3. Two layer of sealing technology is adopted in the pot cover. The opening of the heating mixed cover adopted the air opening device and the opening of the cooling mixed cover adopted hydraulic pressure control system.

4. The electrical control section with the programmable logic control adopted well-known imported meters and control components.

5.It is equipped with the pulse dust-cleaning recovery device.

6. The blades have been passed the test of the dynamic and static balance testing machine

7.you may choose the simple and easy feeding system.

Features of high speed mixing

The technology of sealing mainshaft is given the state patent.

The technology of two layers of sealing is adopted in its pot cover.

It has self-friction heating and electric heating modes.

The discharging mode shave the temperature-automatic control and the manual conrol.

Its blades are made of stainless steel. They passed the test of dnamic balance and static equilibrium.

Its electric control section adopts famous control components and temperature-control meters.

Packing

The mixer unit first wraped with film and packed in wooden cases in case shipping damange

Company Information

Kairong group , headquartered in Nanjing, China, is a global manufacturing and trading company in the field of high-performance plastics and rubber processing equipment , extrusion solutions, masterbatch and compounding, etc. Its unit Nanjing Haisi Extrusion Company is a prefessional manufacturer of twin screw extruder, single screw extruder ,two stage extruder and its related auxiaries. We tailor solutions from raw materials, materials processing equipment, to injection for different customers. Each Kairong solution is designed , manufactured, and commissioned by experienced teams of professionals engineers and aftersales staffs.

Kairong group offers raw materials, Mixing and conveying unit, extrusion technology, recycling unit, profile extrusion etc. We offer whole plant ,even turnkey solution to meet different customers' requirements.

Kairong Group believes that " High quality and profession service will bring bright future "