SJ 80/156 PVC Free Foam Board Production Line

1.Power condition

1.1 Standard: 415V / 3-phase / 50 Hz

1.2 Working voltage: 415V

1.3 Control voltage: 220V

1.4 Protective measures: ground

2.Compressed air

2.1 Effective working pressure range: 0.4 ~ 0.7Mpa

2.2 Conditions of Use: Requirements of dust-free, smoke-free, oil-free

3.Cooling water

3.1 Effective working pressure range: 0.2 ~ 0.4Mpa

3.2 Water temperature: 10 ~ 25 ºC

Main Technical Parameter

1. Production materials: PVC materials;

2. Product width: L = 1220mm;

3. Product thickness: δ = 5-25mm;

4. Output: 350-400Kg / H;

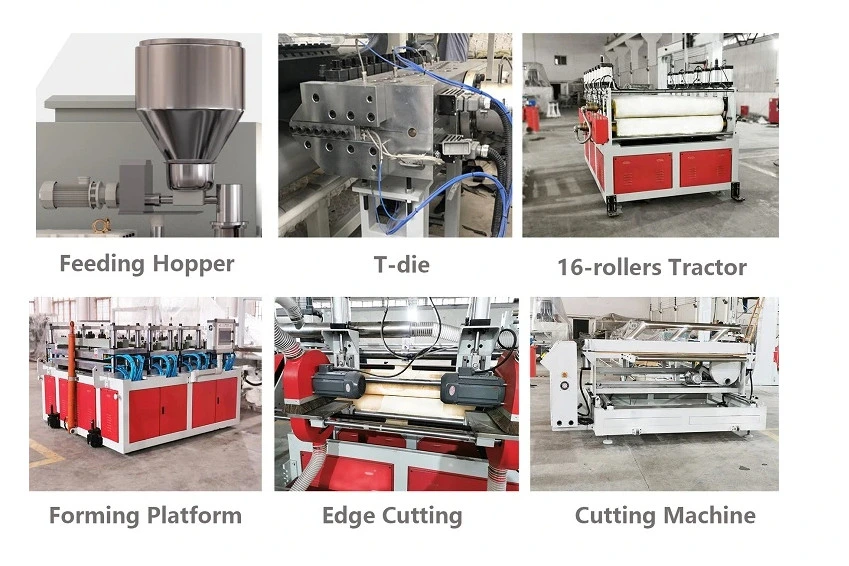

Equipment Structure:

| Item | Equipment Name | Quantity |

| 1 | SJZ80/156 Conical twin screw extruder | 1 set |

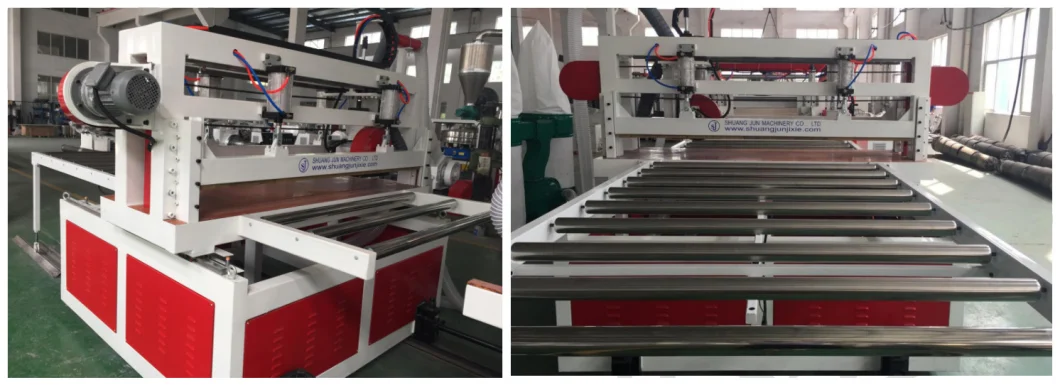

| 2 | L=1500 calibrator table | 1 set |

| 3 | L=1500 Transverse Saw | 1 set |

| 4 | L=1500 Cooling bracket | 1 set |

| 5 | L=1500 edge cutter | 1 set |

| 6 | longitudinal saw | 1 set |

| 7 | Mold temperature machine heating system | 1 set |

| 8 | Back and forth movement device | 1 set |

| 9 | The instrument of Calculate the length | 1 set |

| 10 | Linear Guide Rail | 1 set |

| 11 | Stacker | 1 set |

Production process:

The screw feeder takes the material from the 5m3 silo(~ 3 tons) → The Extruder Feeding Hopper → The extruder → Material Plasticizing → T-die → Forming Platform →Edges Trimming → Roller Cooling Bracket →Air Cooling Cabinet(Optional) → Traction Machine→ Cutting Machine →Automatic Stacking Machine

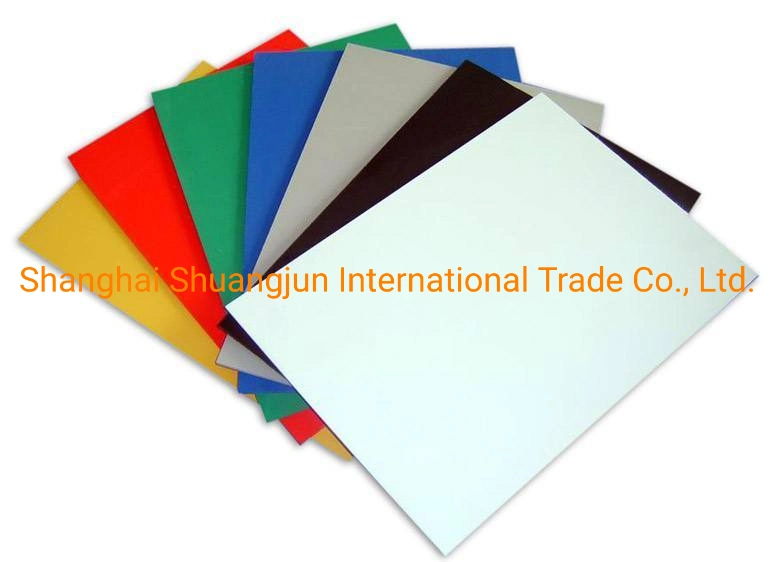

The finished product:

The finished product thickness: 2-30mm

The finished product width: 915mm/1220mm/2050mm

Customization is available!

The Applications:

Transpoartation: steamship, airplane, carriage, train compartment, roof shed, case core layer, inner upholster, etc.

Architecture: building wall board, decoration board, housing, office, public building interlayer, commercial decoration shelf, non-dust room board, ceiling plate, etc.

Advertisement: screen printing, computer lettering, ad board, etc.

Industry: chemical industry antisepticising project, thermoforming, for refrigerator, for temperature keeping, for environment protection, etc.

Other applications: mold plate, sports equipment, breeding equipment, seashore wet-proof facility, water-fast material, art material, various interlayer, etc.

Packing :

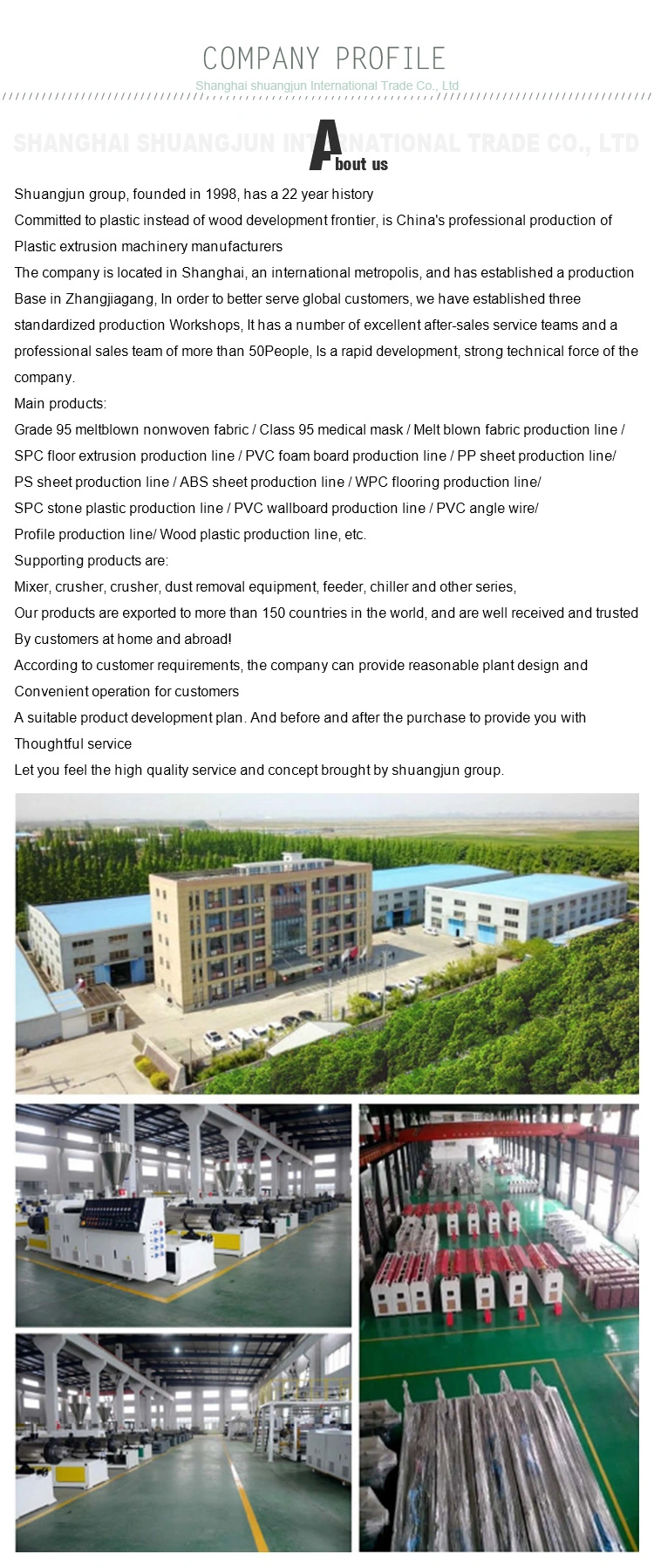

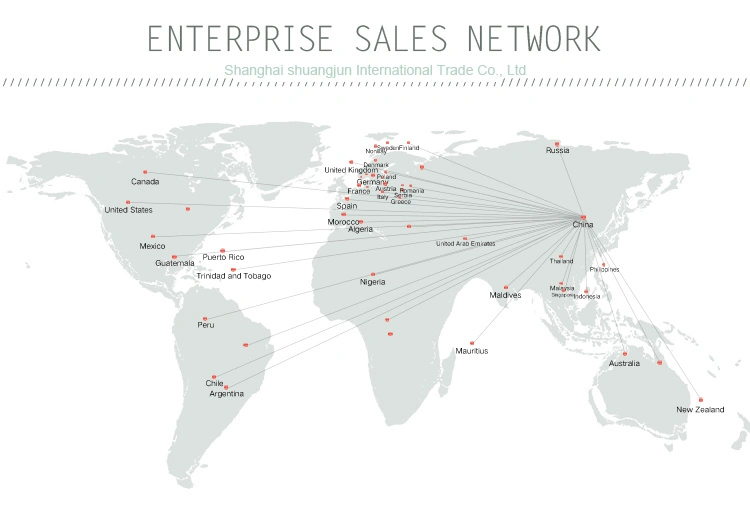

Company Introduction